Stormwater Attenuation Tanks | 60T Load Capacity

Ideal for Heavy-Traffic and Industrial Drainage Projects

YD StormBreaker60® is our highest load-capacity underground stormwater attenuation module, engineered for sites with continuous heavy vehicle traffic. With a 60-ton load rating, it provides reliable structural performance in airports, container yards, logistics terminals, industrial facilities, and major transportation corridors.

Compared with the 32T and 45T models, StormBreaker60® is selected when drainage structures are installed directly beneath heavy-traffic surfaces or areas with repeated dynamic loads. It maintains high water storage efficiency while ensuring long-term stability.

StormBreaker60® can be used as a standalone attenuation system or as part of a Sustainable Drainage System (SuDS), supporting controlled discharge, infiltration, and large-scale sponge city water reuse planning.

Key benefits

• 60-Ton Heavy Load Capacity

Engineered to withstand up to 60 tons of dynamic and static loads, making StormBreaker60® suitable for heavy-traffic parking lots, logistics terminals, highways, and industrial infrastructure.

• High-Strength PP Structural Material

Manufactured from reinforced polypropylene (PP), the module delivers high durability, corrosion resistance, and long service life in demanding ground and climate conditions.

• Superior Compression & Impact Resistance

The internal rib structure provides excellent resistance to long-term compression and repeated vehicle load cycles, ensuring structural stability over time.

• Efficient Use of Underground Space

Despite its high load performance, the compact modular configuration allows for optimized installation depth and efficient land utilization in both dense urban and large-area sites.

• Reliable Stormwater Attenuation & Management

Supports infiltration, temporary storage, and controlled discharge, reducing surface runoff and lowering flood risk in large-scale drainage projects.

• Supports Sustainable Water & Drainage Planning

Promotes groundwater recharge and reduces pressure on municipal drainage networks, aligning with SuDS and sponge-city requirements.

• Simplified Installation & Low Maintenance

Modules are lightweight, easy to transport and assemble, minimizing installation labor and long-term maintenance costs.

Not sure if 60T is the right capacity for your site? Our engineers can run load and depth calculations based on your drawings and project requirements.

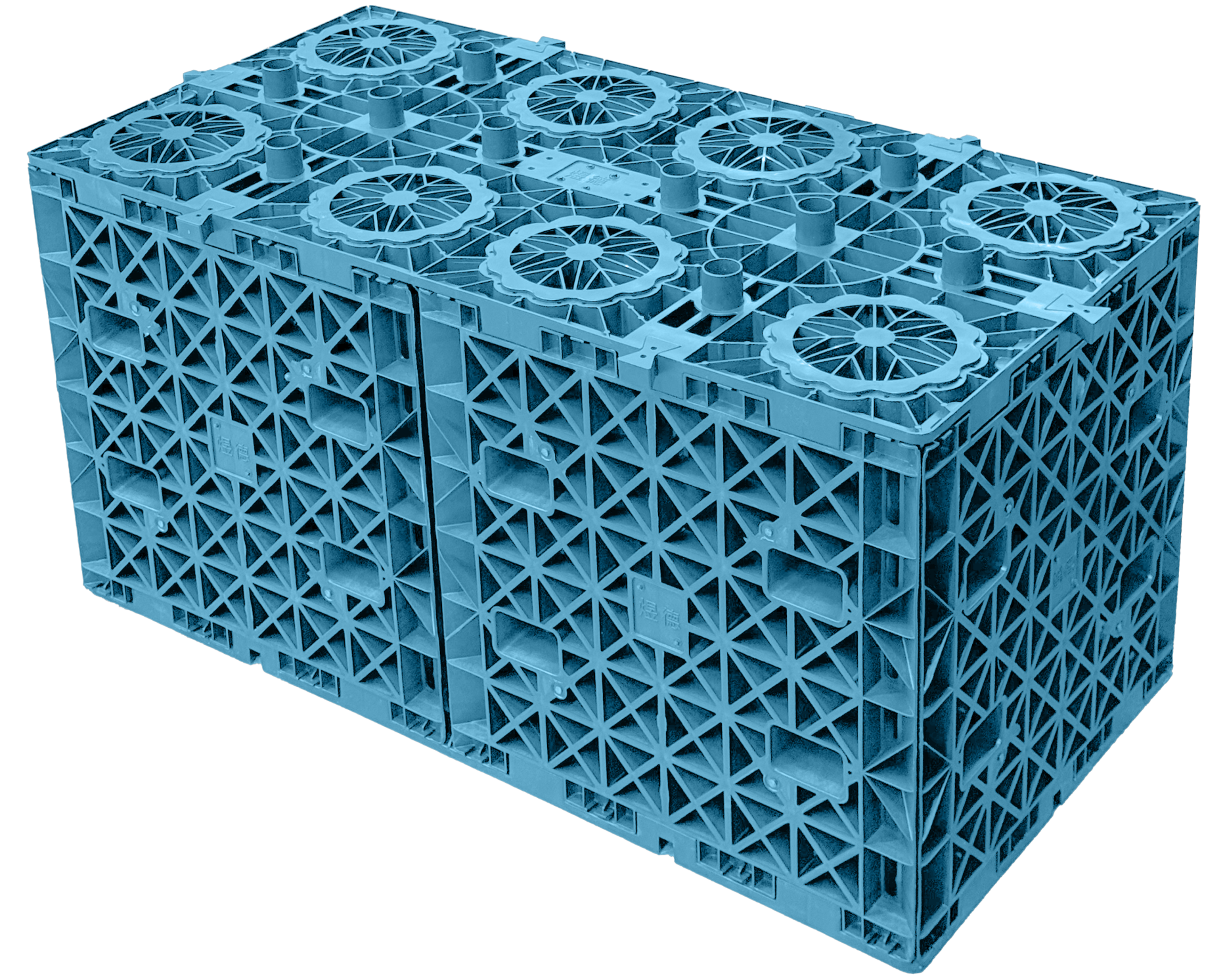

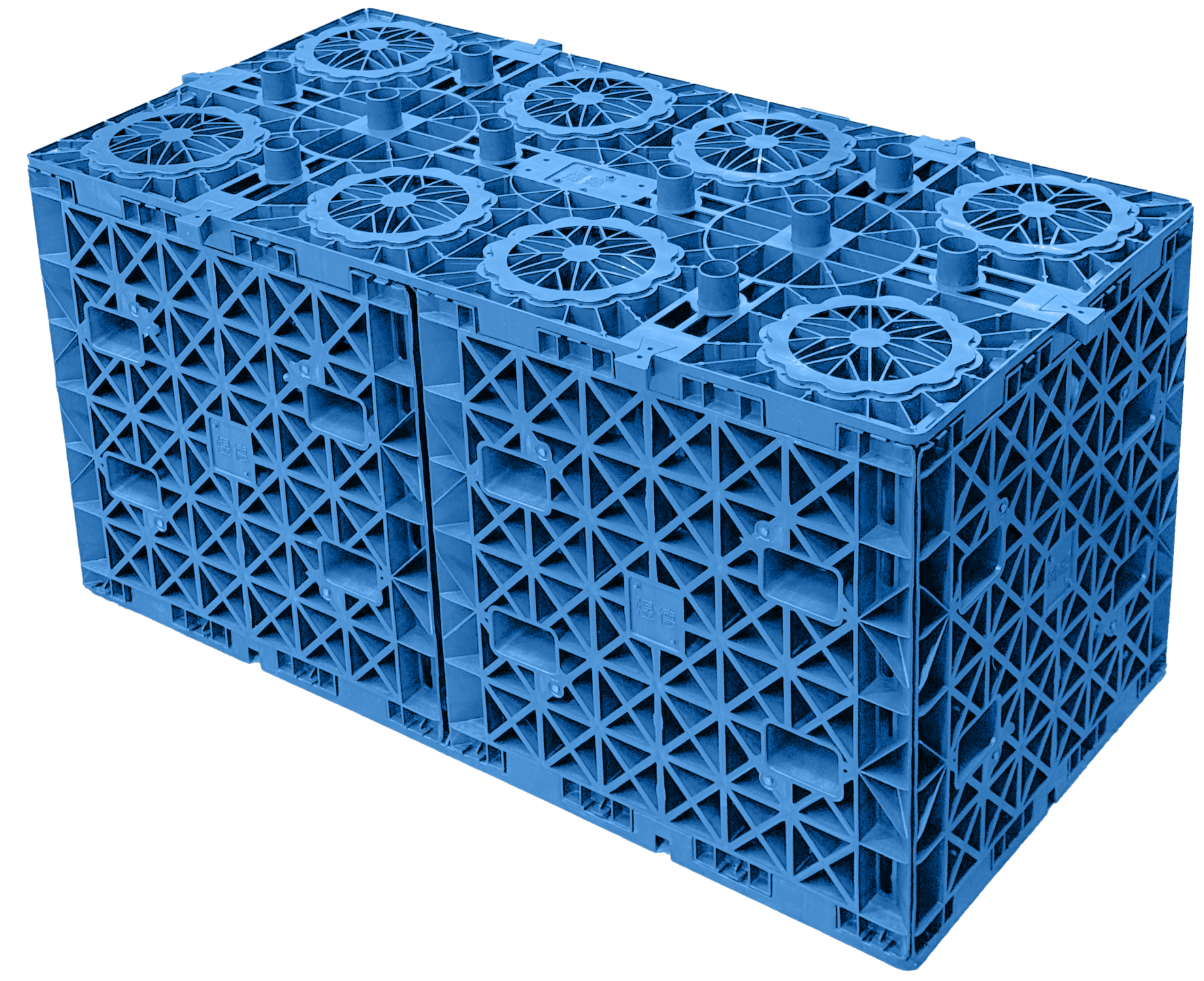

Product Name: YD StormBreaker60®

Product Size: 1000 × 500 × 552 mm / unit

Material: Reinforced Polypropylene (PP)

Color: Blue

Module Weight: 11.12 kg/unit | 4 units = 1 m³ assembled system

Load Rating: 60 tons/m² (higher load ratings available upon request)

Storage Efficiency: Up to 95% effective void ratio for high-volume water retention

Functions & Performance:

• Rainwater Collection: Captures and stores surface runoff efficiently.

• High-Capacity Water Storage: Reduces peak discharge and eases drainage network pressure.

• Retention & Infiltration: Supports controlled release and groundwater recharge.

• Flow Regulation: Prevents drainage overload during heavy rainfall events.

• Water Reuse Capability: Suitable for irrigation, cooling, and non-potable reuse systems.

• Pollution Control: Reduces sediment, suspended solids, and surface runoff pollution.

Installation Efficiency Compared

Installation Efficiency of StormBreaker60® vs Traditional Concrete Systems

| System Type | Installation Speed | Labor Requirements | Site Impact | Maintenance |

|---|---|---|---|---|

| YD StormBreaker60® | 1 m³ ≈ 10 minutes (modular stacking) | 2–3 workers | Minimal excavation, no curing needed | Low |

| Concrete Tank | 1 m³ ≈ 2–3 hours (pour & cure) | 4–6 workers + equipment | Major excavation, curing time required | Medium–High |

Compared with traditional concrete tanks, StormBreaker60® requires less excavation, no curing period, and faster assembly, allowing projects to stay on schedule with lower labor demand and minimized site disruption. This makes it particularly suitable for sites with limited shutdown windows, high traffic flow, or strict construction timelines.

StormBreaker60® also provides consistent load performance over time, unlike concrete structures which may crack or degrade under repeated dynamic vehicle loads.

Compare other models:

Where are The 60T Load Capacity Required?

YD StormBreaker60® is designed for areas exposed to heavy vehicular loads and frequent surface traffic. It provides reliable underground stormwater attenuation in locations where structural strength and long-term stability are critical.

Typical Application Areas:

Heavy-Traffic Parking Lots

Commercial plazas, shopping malls, and large retail centers.Main Roads & Highways

Continuous vehicle movement and dynamic traffic loads.Large Industrial Zones

Warehouses, production facilities, and distribution centers.Airport Runways & Taxiways

Extreme axle loads from aircraft and service vehicles.Logistics Hubs & Transport Terminals

Freight yards, cargo stations, and trucking depots.High-Traffic Public Infrastructure

Bus terminals, metro transfer hubs, and municipal transport stations.Large Commercial Complexes

Corporate parks, exhibition complexes, and campus developments.

StormBreaker60® is engineered for heavy-load urban drainage, ensuring structural safety and efficient stormwater retention in large-scale infrastructure.

If you are unsure which load capacity suits your project, our engineering team can help evaluate site conditions and design the appropriate system.

Fast Deployment & Delivery Commitment

Fast Deployment, Global Delivery

We understand that time is critical for infrastructure and municipal projects. That’s why we offer:

Lead Time Commitment: Standard production and delivery in 7–14 working days (depending on order volume and destination).

In-Stock Units Available: 60T modules are pre-stocked for urgent orders in select regions.

Flexible Shipping Options: Sea, air, and land logistics available through our global freight partners.

Documentation Ready: All export documents (CO, B/L, CE, test reports) can be prepared within 3 business days.

Need urgent delivery? Contact us to check current stock status and local distributor availability.

Product Specifications

Specification | Application Area | Performance & Benefits | Maintenance Guidance |

|---|---|---|---|

| Product Name | YD StormBreaker60® | High load-bearing geocellular stormwater attenuation system | Inspect structural condition annually |

| Module Size | 1000 × 500 × 552 mm / unit | Flexible modular depth and layout planning | Confirm backfill density stability |

| Material | Reinforced Polypropylene (PP) | Corrosion & fatigue resistant under dynamic loads | Avoid sharp debris contact |

| Color | Blue (Customizable) | Color coding helps system classification | No special coating needed |

| Module Weight | 11.12 kg/unit | Lightweight, reduces installation labor | Verify load distribution alignment |

| Load Capacity | 60 tons/m² | Suitable for heavy vehicle traffic zones | Inspect backfill to avoid settlement |

| Storage Efficiency | Up to 95% void ratio | High-volume stormwater retention | Check inlet/outlet flow paths periodically |

| Performance Modes | Attenuation / Infiltration / Controlled Discharge / Reuse | Supports SuDS & sponge-city planning | Flush if sediment accumulation is observed |

StormBreaker60® is recommended for airports, logistics terminals, highways, distribution centers, industrial complexes, and other locations with continuous heavy vehicle loads.

Need support selecting the correct load rating (32T / 45T / 60T)? Our engineering team can evaluate site conditions and recommend the appropriate system configuration.

Installation steps

1. Site Preparation

Survey the Site: Conduct a site survey to assess the conditions (e.g., soil type, water table, traffic load) and determine the optimal installation location.

Excavation: Excavate the ground to the required depth and size to accommodate the modules. The trench should be wide enough to allow for proper installation and water flow.

Level the Base: Ensure the base of the trench is level and compacted to provide a stable foundation for the modules.

2. Foundation and Bedding Layer

- Install Bedding Material: Lay a bedding layer (usually crushed stone or gravel) at the bottom of the trench. This ensures proper drainage and provides support for the modules.

- Compact the Bedding: Compact the bedding material to create a firm base for the modules, ensuring a stable, uniform surface.

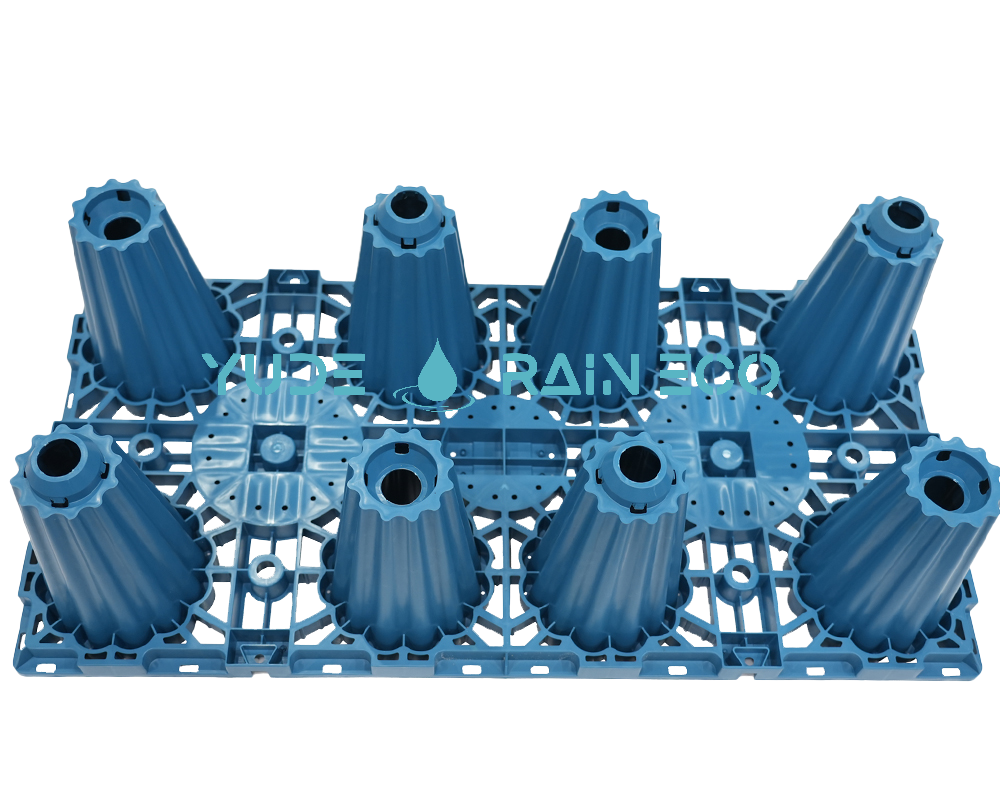

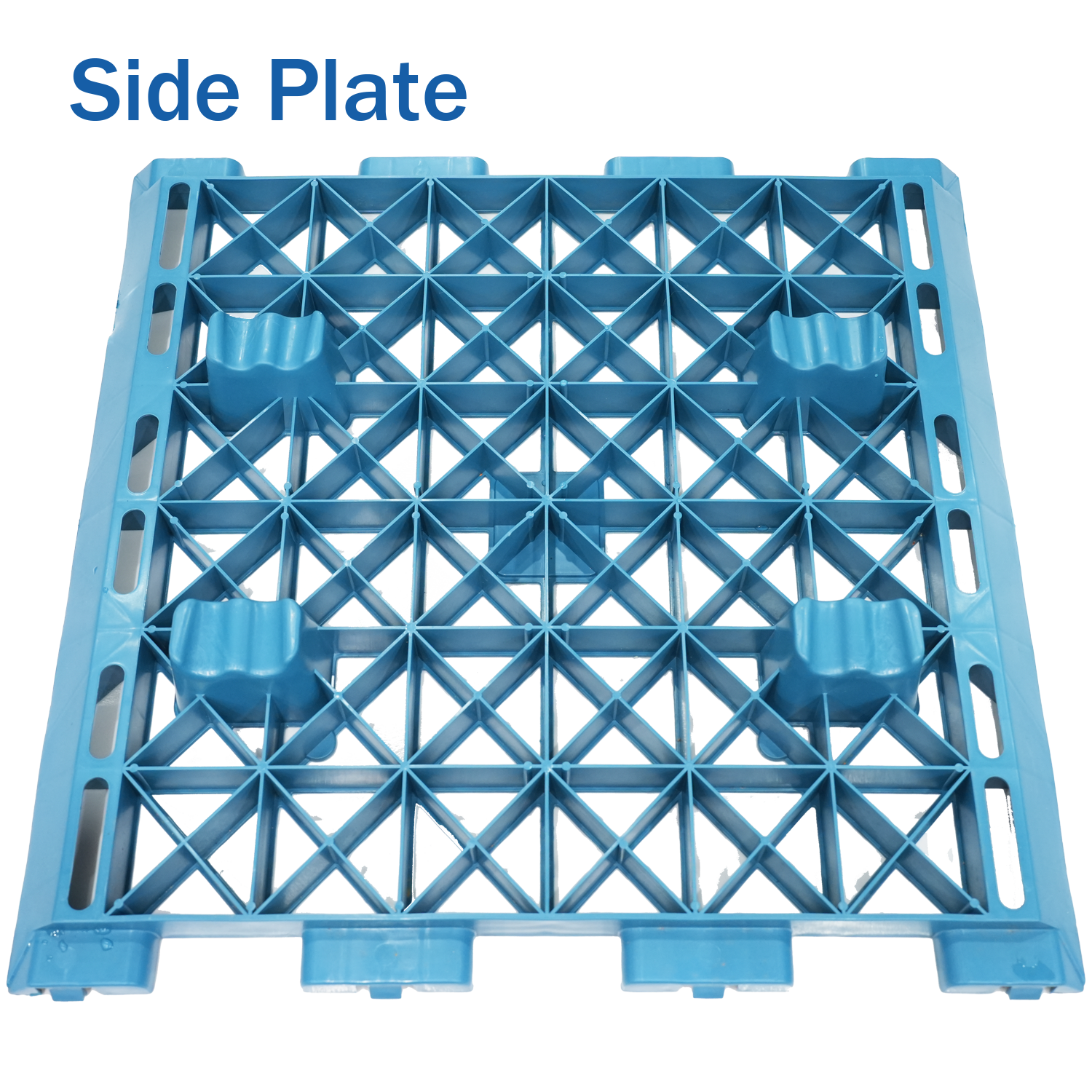

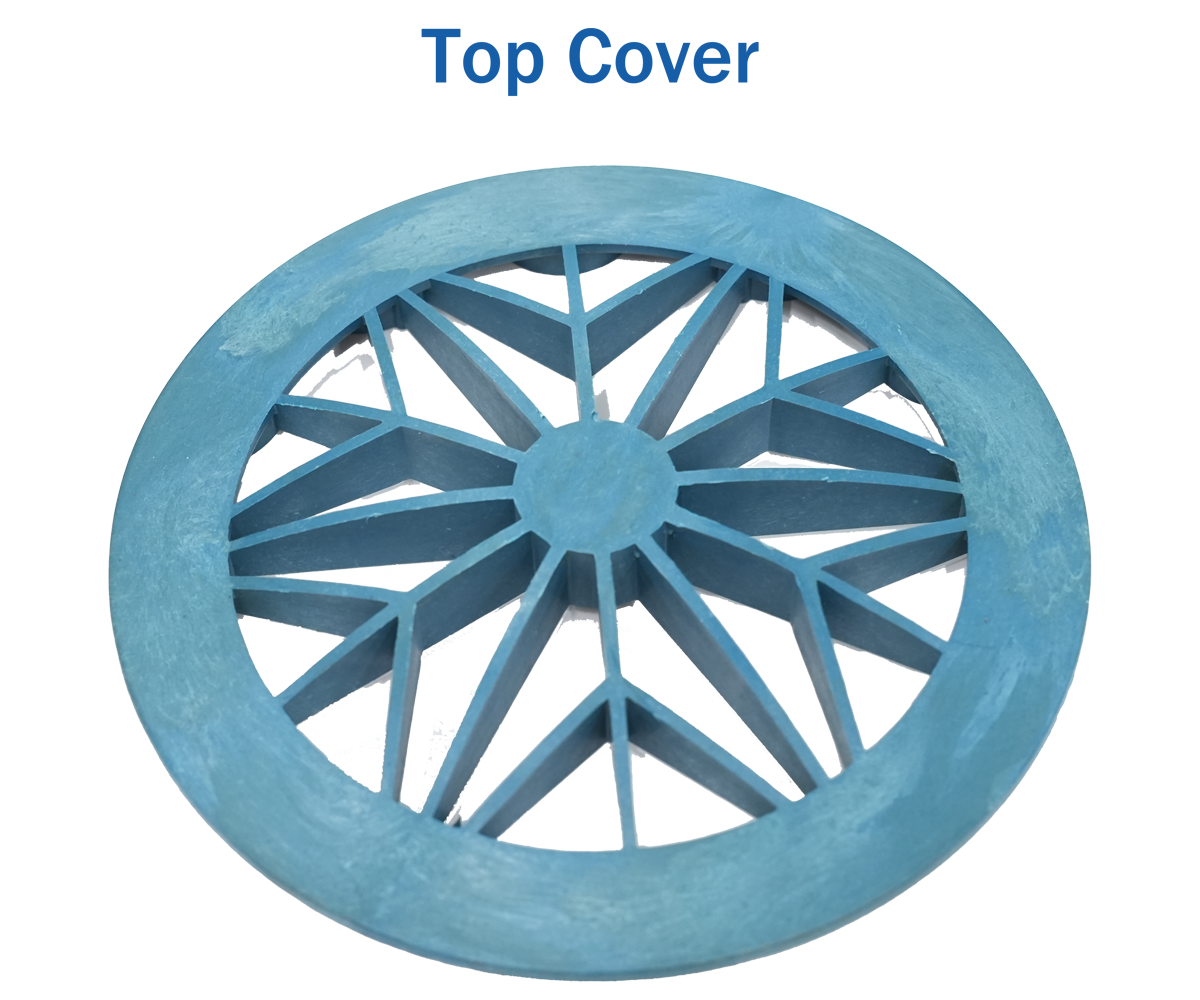

3. Stormwater Attenuation Tanks Placement

- Position Attenuation Tanks: Carefully place the YD StormBreaker32® attenuation tanks into the trench. Ensure that the tanks are aligned properly and the connectors (if applicable) are facing the correct direction.

- Stacking (if applicable): If stacking is required, ensure that the rainwater attenuation tanks are stacked in a stable and secure manner, following the Yude Rain Eco’s guidelines.

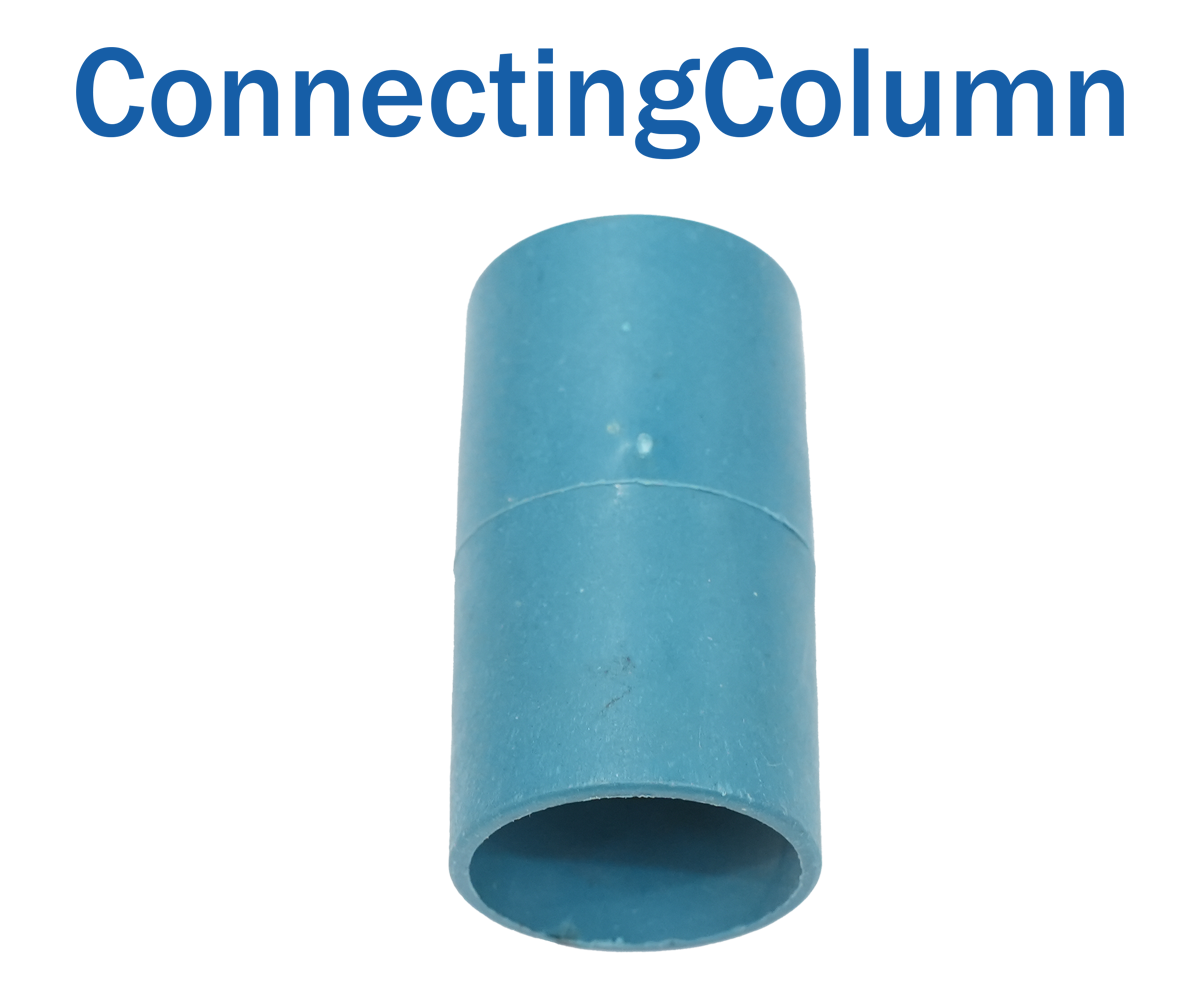

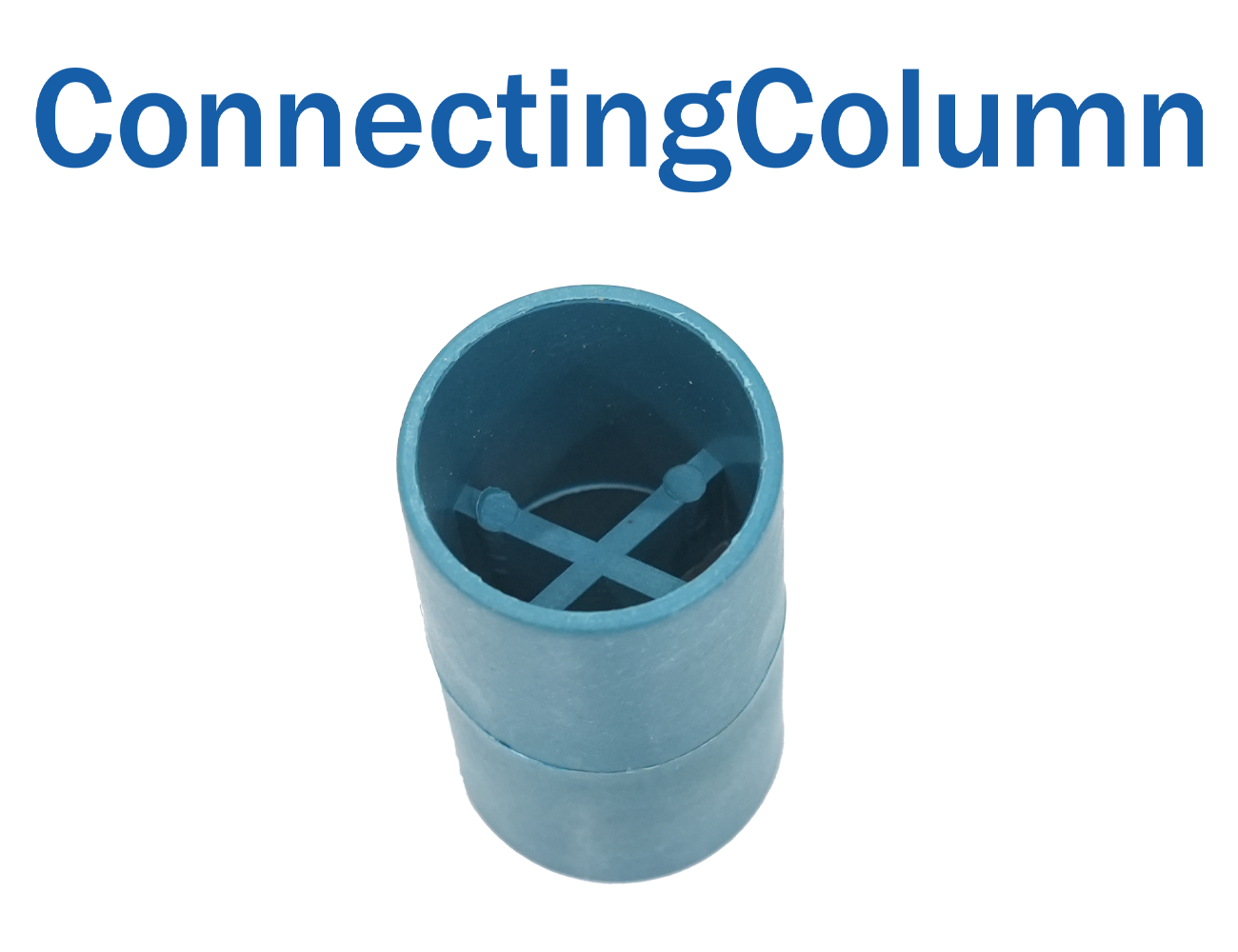

4. Stormwater Attenuation Tanks Connection

- Connect Stormwater Attenuation Tanks: Depending on the system design, connect the Stormwater Attenuation Tanks using interlocking mechanisms or connectors to ensure the system is secure and watertight.

- Connect to Drainage System: Link the Stormwater Attenuation Tanks to the surrounding stormwater drainage system, ensuring proper inlet and outlet connections for water flow.

5. Backfilling

- Backfill Around Tanks: Once the tanks are in place and connected, backfill the trench with appropriate material (e.g., gravel or sand) around the tanks. Avoid using materials that could cause compaction or block water flow.

- Compact the Backfill: Gently compact the backfill to ensure stability without damaging the tanks.

6. Installation of Surface Layer

- Reinforce Surface: Install a surface layer (e.g., asphalt or concrete) above the stormwater attenuation tank system, depending on the application (e.g., road, parking lot, or green space).

- Ensure Proper Drainage: Make sure that the surface layer allows for proper water drainage into the tanks. This is particularly important for areas like roads or parking lots.

7. Final Inspection & System Testing

- Inspect Alignment & Connections: Ensure all tanks are properly aligned, with secure connections and no gaps.

- Test the System: Simulate rainfall or runoff to verify water flows correctly through the tanks, checking for any leaks, blockages, or drainage issues.

8. Maintenance and Monitoring

- Establish Maintenance Schedule: Set up a regular inspection and cleaning schedule to ensure the system continues to function optimally.

- Monitor for Damage or Blockages: Check the system periodically for signs of damage or blockages and address any issues promptly.

Quality Assurance Showcase

FAQ

Stormwater attenuation tanks is a specially designed system used to capture, store, and manage rainwater runoff. It helps to prevent flooding by controlling how water is drained away from urban and industrial areas.

YD StormBreaker60® offers the highest load capacity at 60 tons per square meter, making it ideal for the most demanding applications, such as airports, heavy industrial zones, and large commercial developments.

Routine inspections are recommended every 6 months to ensure the system remains free from blockages and damages. After extreme weather events, the system should be checked for debris and blockages.

Yes, YD StormBreaker60® is made from recyclable polypropylene, making it an environmentally friendly solution for stormwater management. Additionally, it helps mitigate flood risks, protecting natural water sources and reducing runoff pollution.

The installation process is efficient but requires careful planning and preparation. A qualified contractor is recommended to ensure the system is installed properly, especially in areas where heavy loads or complex water management are required.

YD StormBreaker60® is designed primarily for permanent installations due to its durability. However, it can also be used in temporary or short-term stormwater management applications, such as during construction or large-scale events.

Load rating selection depends on surface use conditions (vehicle type, frequency, axle weight, and soil depth). Our engineering team can evaluate your drawings and recommend the correct configuration.

Upload your site layout or project details in the request form, and we will provide a report.

Need a stormwater solution that can handle extreme traffic loads?

Request a load calculation report and technical drawing based on your project requirements.