1. Summary: The Importance of Underground Water Storage in Cold Climates

Overview of StormBreaker® and its Relevance in Stormwater Management

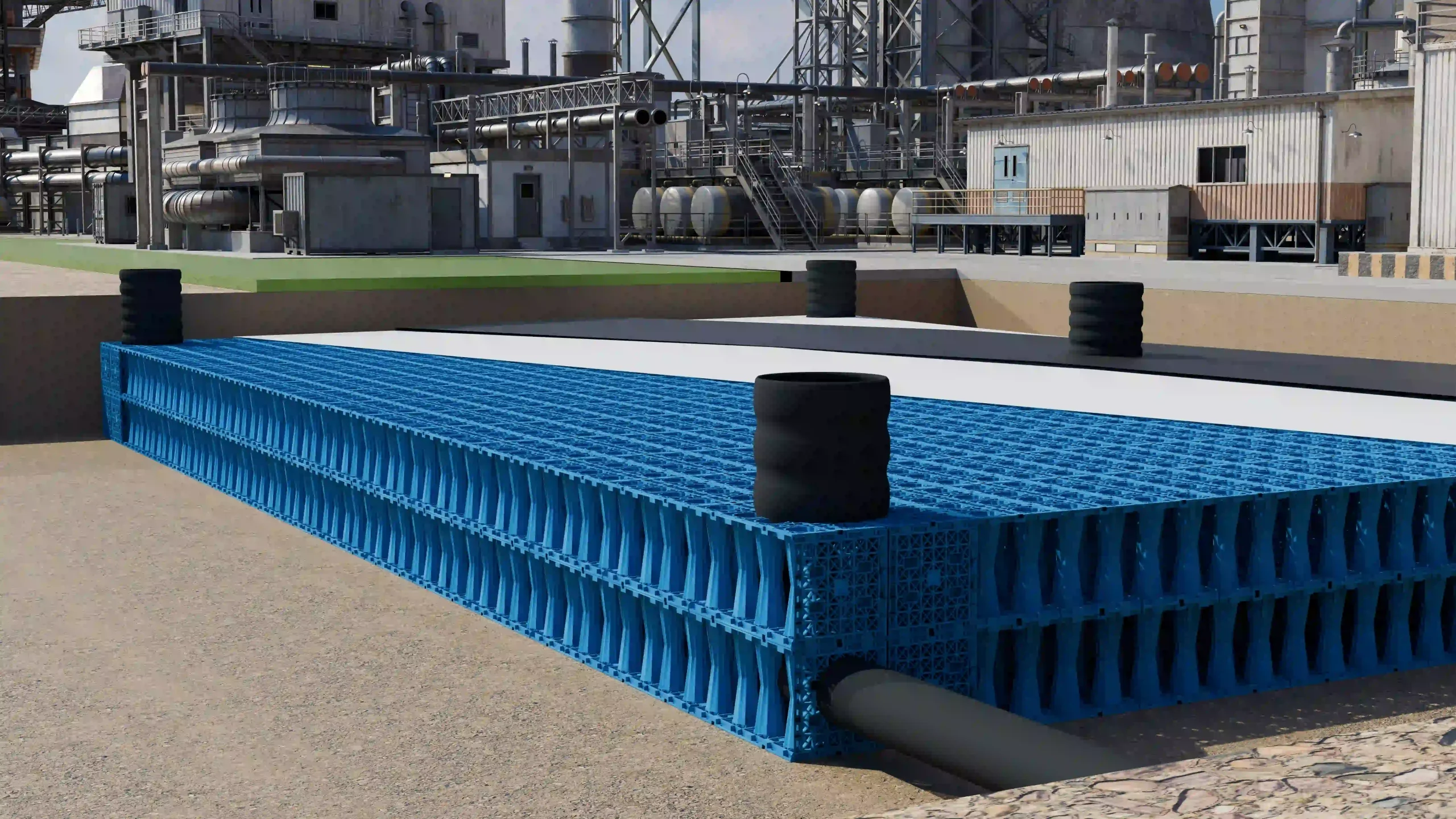

YudeRainEco’s StormBreaker® is a cutting-edge solution designed to manage stormwater efficiently and sustainably. It is an underground modular attenuation system that provides substantial storage for rainwater, helping to mitigate flooding by absorbing and controlling excess runoff during heavy rainfall events. StormBreaker® is particularly effective in both residential and commercial settings, offering a robust alternative to traditional surface storage methods.

The system is constructed using Polypropylene (PP), a material known for its durability, resistance to low temperatures, and high strength-to-weight ratio, making it an ideal choice for stormwater infrastructure. StormBreaker® plays a crucial role in stormwater retention, infiltration, and flood mitigation by slowing the movement of stormwater, reducing the risk of downstream flooding, and enabling water to slowly infiltrate the ground. The system also offers additional benefits, such as reducing urban heat islands and promoting groundwater recharge, essential components in managing urban water cycles sustainably.

With increasing urbanization and changing weather patterns, efficient stormwater management has become more critical than ever. StormBreaker® is designed to meet these challenges, providing reliable, long-term solutions for cities and regions facing more frequent and intense rainfall events.

Addressing the Concern: Can Underground Stormwater Cisterns – StormBreaker® Function Properly in Cold Climates?

As stormwater systems become integral to urban infrastructure, concerns arise regarding their ability to function efficiently in cold climates. In particular, areas where winter temperatures regularly drop to sub-zero levels face unique challenges when it comes to underground stormwater storage.

One key concern is whether underground stormwater cisterns – StormBreaker®, designed for year-round performance, can continue to operate effectively in freezing conditions. The central issue is whether the stored water in the system will freeze, potentially compromising the system’s integrity and functionality. The freeze-thaw cycle in cold regions can lead to water expanding as it freezes, potentially damaging the infrastructure. Furthermore, in extremely cold conditions, does the material — Polypropylene (PP) — remain durable and capable of withstanding freezing pressures?

Understanding how underground stormwater cisterns- StormBreaker® behaves in freezing temperatures, both in terms of its material performance and its ability to store water without freezing, is crucial for determining its viability in cold climates. Thus, it’s important to evaluate whether the system can be installed and operated safely and effectively when surface air temperatures fall below freezing.

Objective of the Article

This blog aims to provide a comprehensive, scientifically backed analysis of underground stormwater storage tanks StormBreaker®’s performance in cold climates. It will explore whether this innovative underground stormwater solution can function effectively in environments where surface temperatures regularly drop to sub-zero levels. By reviewing factors such as frost depth, thermal inertia, and the material properties of PP, we aim to offer clear insights into the system’s ability to operate without freezing under harsh winter conditions.

The article will also discuss best practices for installation in cold climates, offering recommendations to ensure that underground stormwater cisterns StormBreaker® can continue to provide reliable stormwater management while minimizing the risk of freezing. Through this analysis, the goal is to equip engineers, developers, and planners with the information needed to safely incorporate underground stormwater cisterns StormBreaker® into cold-climate projects.

2. Understanding Frost Line, Soil Freezing, and Thermal Inertia

Frost Line (Freezing Depth) and Its Impact on Underground Systems

Definition of the Frost Line

The frost line (also called freezing depth or frost penetration depth) refers to the maximum depth at which the soil freezes during the coldest part of the year. Soil above this depth is susceptible to freezing due to low air temperatures, while soil below this depth generally remains above 0°C, preventing freezing. This depth is influenced by multiple factors, including climate, soil type, moisture content, ground cover (e.g., snow, vegetation, pavement), and heat sources (e.g., geothermal heat, underground water flow). (en.wikipedia.org)

The frost line is not a fixed value and varies greatly depending on location and climate. For example, in temperate climates, the frost depth may be less than 1 foot (30 cm), while in colder northern regions, it can exceed 5–8 feet (1.5–2.4 meters). (en.wikipedia.org)

Influence on Underground Installations (Why Frost Line Matters for Cisterns/Tanks)

For underground infrastructure, such as water pipes, cisterns, and foundations, the frost line is a critical design parameter. The reasons are as follows:

-

If an underground structure, such as a water tank or pipeline, is installed above the frost line, the surrounding soil can freeze during cold temperatures, causing frost heave. This can lead to structural damage, misalignment, and potential failure. (onlinepubs.trb.org)

-

For water storage systems like StormBreaker®, if the system is located within the freezing zone, the stored water can freeze, causing the volume to expand (roughly 9% when freezing), putting pressure on the system’s structure. This can result in cracking, bursting, or complete system failure. Many building codes require water pipes and structures to be buried below the frost line to avoid freezing and prevent structural damage. (powerblanket.com)

-

Therefore, installing an underground storage system below the frost line ensures that the surrounding soil and water remain unfrozen, thus avoiding freezing-related damage.

In conclusion, understanding the local frost line depth is the first step in determining whether an underground water storage system like StormBreaker® can safely function during cold climates.

Thermal Inertia and Soil Freezing Dynamics

What is Thermal Inertia in Soil?

Thermal inertia refers to the ability of a material (such as soil) to resist changes in temperature. In the context of underground systems, thermal inertia means that soil temperatures change more slowly than air temperatures, especially in the deeper layers. Soils possess a certain heat capacity (the ability to store heat) and thermal conductivity (the rate at which heat is transferred), which helps to maintain warmer temperatures in the soil during colder months.

This property of thermal inertia means that even in regions with severe winter temperatures, the soil below a certain depth often remains relatively warm, preventing freezing. Many systems, such as ground-source heat pumps, rely on this principle. Even when surface air temperatures drop drastically, underground pipes (buried a few meters deep) maintain a temperature above freezing due to the soil’s heat retention. (cedengineering.com)

Thus, for underground water systems like StormBreaker®, if buried deep enough, the surrounding soil will likely buffer the freezing temperatures and keep the stored water above 0°C, reducing the risk of freezing. This buffer is particularly important in cold climates where surface air temperatures may be well below freezing for extended periods.

Ground Freezing and Thawing Dynamics

The process of ground freezing and thawing involves complex thermal dynamics, including heat conduction, phase change (from liquid to ice), and water migration (including the formation of ice lenses).

-

When surface temperatures remain below 0°C for extended periods, heat from the soil surface dissipates, causing a freezing front to develop and progressively penetrate deeper into the soil. The depth of freezing depends on air temperature, the duration of cold weather, soil conductivity, moisture content, and the soil’s density. (onlinepubs.trb.org)

-

Studies show that the cumulative freezing degree-days (FDD) — the number of days with temperatures below freezing — can be used to predict the depth of frost penetration. This is a helpful method for estimating how deep the freezing front will advance in a given region. (msaag.aag.org)

-

However, snow cover and other surface coverings (e.g., vegetation, pavement) can significantly reduce heat loss from the ground, slowing down the freezing process. Even if the air temperature is low, the soil underneath may stay warmer than the surface. For example, regions with snow cover or other insulating layers will experience less deep soil freezing than areas with bare soil. (fs.usda.gov)

-

Additionally, the type of soil plays a major role in how quickly the ground freezes. Coarse-grained soils (such as sand and gravel) have higher thermal conductivity and freeze more quickly than fine-grained soils (such as clay and silt), which retain heat and freeze more slowly. (pavementinteractive.org)

Thus, the depth of freezing in the soil depends not only on air temperature but also on the soil’s composition and moisture content, as well as the surface cover. Therefore, the depth to which the frost line penetrates the ground is not a fixed value, and it varies depending on the location and conditions.

Supporting Studies and Data

-

A detailed study by the CRREL-Gandahl Laboratory monitored frost depth in northern climates using frost tubes (a method to measure soil freezing depth). The research (2008-2011) compared soil freezing penetration across different regions and showed that Freezing Degree-Days (FDD) was an effective predictor of frost depth. The study also demonstrated how the freezing process can be modeled using FDD. (static1.squarespace.com)

-

Another study, conducted during the 2019-2020 winter in Minnesota on peatland sites, explored the impact of snow cover on soil freezing. It showed that snow cover can significantly slow down the freezing process, keeping the upper layers of soil (up to 20 cm) from freezing even during extreme cold spells. In contrast, when the snow cover was removed, the ground froze much more rapidly. (fs.usda.gov)

-

These studies highlight the influence of snow cover and soil properties in moderating the freezing depth, which is key to understanding the behavior of underground systems like StormBreaker®.

Implications for StormBreaker® and Underground Rainwater Storage

Applying the principles of frost line, thermal inertia, and soil freezing dynamics to underground water storage systems like StormBreaker®, we can infer the following:

-

If StormBreaker® is buried below the local frost line (considering the maximum possible frost depth and an additional safety margin), the surrounding soil and water are unlikely to freeze, as the soil acts as a thermal buffer.

-

In regions with clay or silty soils (high density, slow thermal conductivity, and higher moisture content), the freezing front is slower, and soil is more resistant to deep freeze, creating a more stable environment for underground systems.

-

Snow cover or other insulating layers (such as vegetation, mulch, or pavement) further enhance the likelihood that underground systems will remain unfrozen during winter, as they reduce heat loss from the ground.

Thus, frost line depth, soil type, surface cover, and installation depth should be the primary factors in determining whether StormBreaker® will function effectively in cold climates, rather than relying solely on surface air temperature.

3. The Role of Soil Type and Moisture Content

Soil Composition and Freezing Behavior

Impact of Soil Type on Freezing

The behavior of freezing and thawing soils — and how deeply frost penetrates — depends heavily on soil type (particle size distribution, texture, compaction, permeability). Research shows that soils differ in their “frost‑susceptibility,” which describes the likelihood and magnitude of freezing-related deformation (e.g., frost heave). onlinepubs.trb.org+2NSF Par+2

-

Fine‑textured soils (clays, silts): These typically have low permeability and small pore sizes, which limit capillary water flow — a condition that reduces ice‑lens formation and thus reduces frost heave compared with more susceptible soil types. ScienceDirect+2onlinepubs.trb.org+2

-

Coarse / light‑textured soils (sands, gravels, loamy sands): These tend to freeze more deeply, because their larger pore spaces allow faster water migration and ice lens formation; the soil frost depth and freeze‑thaw impacts tend to be greater. MDPI+2ntnu.no+2

A recent experimental study on frost susceptibility comparing clayey vs sandy soils under repeated freeze–thaw cycles found that both soil types exhibited frost heave, but the magnitude and behavior differed significantly depending on soil type, permeability, moisture supply, and external water sources. NSF Par

Thus, soil type is fundamental — it’s not just about whether the ground will freeze, but about how freezing propagates (depth, ice‑lens formation, soil deformation) which determines the risk to any underground infrastructure.

Moisture Content’s Role in Freeze Behavior

Soil water content (moisture) plays a pivotal role in freezing behavior. Key findings:

-

Soils with higher moisture content (pore water) — especially when combined with sufficient permeability — supply water to the freezing front, enabling the formation of ice lenses, which drive frost heave. onlinepubs.trb.org+2onlinepubs.trb.org+2

-

Conversely, soils with low permeability (e.g., dense clays) may retain moisture but inhibit capillary flow, reducing water migration toward ice‑lens formation zones; this suppresses or slows down frost‑heave, even under freezing conditions. ScienceDirect+1

-

Experimental evidence: in one study subjecting clay and sandy soils to ten freeze–thaw cycles, frost heave occurred in both, but the amount and rate of heave varied: clay soils — despite being less permeable — exhibited significant heave under certain moisture and water supply conditions, showing that moisture supply (external or pore water) matters. NSF Par

Therefore, both soil texture and moisture conditions must be considered together; a dry sandy soil may freeze deeply but lack frozen water expansion issues, while a moist clay soil may resist deep freezing but still have localized freeze–thaw stress or ice‑lens formation under certain conditions.

Real‑world Evidence and Study Findings

-

In forest‑soil field experiments, researchers observed that coarse‑textured soils (e.g., sand, loamy sand) developed deeper soil frost than fine‑textured soils (e.g., clay, sandy loam). MDPI

-

The classic frost‑heave mechanism is associated with formation of “ice lenses” — layers of ice that grow within freezing soil, driven by capillary suction of pore‑water to the freezing front. onlinepubs.trb.org+2onlinepubs.trb.org+2

-

Soils with a higher proportion of fines (clay/silt) tend to have lower frost penetration depth under the same freezing conditions compared with sandy soils, due to reduced permeability and slower water migration. onlinepubs.trb.org+2Massachusetts Institute of Technology+2

These findings are widely accepted in cold‑regions geotechnical engineering and form the basis for frost‑protected foundation design, frost‑heave mitigation, and determining suitability of soils for underground structures in freezing zones.

Implications for Underground Water Storage Systems StormBreaker® Installation

Given the above soil‑freezing dynamics, what does this mean for installing StormBreaker® underground in regions subject to freezing winters?

Ideal Soil Conditions for Installation

For underground water‑storage tanks like StormBreaker®, the most favourable soil conditions for avoiding freezing risk would be:

-

Fine‑textured, dense soils (e.g., clays, silty clays, heavy silts) that have low permeability and small pore size — these soils inhibit capillary water migration, thereby reducing the likelihood of ice‑lens formation and frost heave.

-

Moderate but controlled moisture content — soils should not be saturated or have pathways for excess water supply during freezing season. Overly wet soils with high hydraulic connectivity may feed ice‑lens formation.

-

Compacted / well‑graded backfill or natural soil with controlled moisture conditions — ensuring uniformity in soil around the tank, minimizing macropores or preferential flow paths that might channel water toward freezing fronts.

-

Good drainage design — avoid stagnant groundwater or perched water tables near the tank; water accumulation near the tank increases freezing risk.

-

Preferably some insulating or ground‑cover layer above ground (snow cover, vegetation, pavement, mulch) to reduce heat loss from the ground during winter; such coverage slows freezing front progression.

Case Studies / Practical Examples (or Where Soil Type Informed Installation)

While there appear to be limited publicly available documented case studies of large underground cisterns specifically — much of frost‑heave literature deals with pipelines, foundations, pavements — the principles are directly transferable. For example:

-

In road or building foundation engineering in cold regions, designers routinely avoid sandy soils for frost‑susceptible structures; instead, they prefer clayey soils or use frost‑protected design details (insulation, proper backfill, drainage) to prevent damage. Massachusetts Institute of Technology+2ntnu.no+2

-

Soil‑freezing studies in natural environments (e.g., forest soils) show that coarse soils (sands) lead to deeper frost penetration — hence, infrastructures buried in such soils require deeper burial or insulation measures to avoid freezing risk. MDPI+1

Although no public papers describe large plastic cistern installations under these soil regimes, the geotechnical and soil‑freezing research provides a well‑established theoretical basis: with appropriate soil type and installation design, frost risks can be managed.

What This Means for Underground Water Storage Tanks StormBreaker® Deployment in Cold Regions

-

Soil type and moisture content are among the most critical factors affecting whether the underground storage system will remain unfrozen in cold climates.

-

Fine‑grained, low‑permeability soils (clay/silty clay) with controlled moisture and good compaction/backfill are ideal for underground cistern installations in freezing zones.

-

Coarse, sandy, or gravelly soils pose higher risk due to deeper frost penetration and greater potential for ice‑lens formation; such soils require more conservative installation strategies (e.g., deeper burial, insulation, drainage).

-

Good drainage and moisture management are essential to prevent saturation or water supply to freezing fronts.

-

Design and installation must be site‑specific — soil investigation (texture, permeability, moisture), groundwater level, drainage capacity, and backfill quality must be assessed before installation to minimize freeze risk.

4. The Importance of Installation Depth and Frost Protection

Installation Depth and Its Role in Preventing Freezing

Frost Depth Recommendations for Underground Water Systems

Proper burial depth is one of the most important — and commonly adopted — engineering strategies to protect underground water systems from freezing. Many plumbing and building‑code guidelines specify minimum burial depths or require installation below the “frost line” (freezing depth) to avoid freezing of pipe water or stored water. codes.iccsafe.org+2Powerblanket+2

-

According to a typical guideline, exterior water supply piping should be installed not less than 6 inches (≈ 150 mm) below the frost line, and also at least 12 inches (≈ 300 mm) below the ground surface. codes.iccsafe.org+1

-

In colder regions where frost penetration is more significant, water‑line burial depths are often greater. Some recommendations for cold climates call for burial depths of 4 feet (≈1.2 m) or more to ensure adequate protection against freezing. Heat-Line Freeze Protection Systems+1

-

Another reference indicates that water lines may typically be buried between 18 inches (≈ 0.45 m) and 5 feet (≈ 1.5 m) depending on local climate, soil conditions, and system type. B&L Plumbing+1

Although much of this guidance concerns pipes rather than large cisterns, the same principle — burying below frost penetration depth — holds true for any underground water storage system, since both require preventing the water from exposure to freezing temperatures.

How Deep Should Underground Water Storage Systems StormBreaker® Be Installed? Suggested Depths by Climate Zone

When applying these principles to a modular underground cistern such as StormBreaker®, reasonable installation-depth suggestions (depending on climate) are:

| Climate / Frost Severity | Suggested Installation Depth (top of cistern) |

|---|---|

| Mild / temperate (light frost) | Just below local frost line + ≥ 0.3 m below ground surface — often 0.5–1.0 m total depth. |

| Moderate cold (seasonal frost, moderate freeze) | ≥ 1.2 m (4 ft) burial depth — ensures the cistern lies well below typical freezing penetration. |

| Severe cold / deep frost region (long winters, deep frost penetration) | ≥ 1.5 m (5 ft) or deeper — ideally below maximum historical frost depth plus safety margin. |

These are guidelines, not universal prescriptions — the “right depth” depends on local frost‑penetration data, soil thermal regime, historical freeze history, and site geology.

By installing StormBreaker® below the local frost line with adequate safety margin, you leverage the insulating and buffering effect of the surrounding soil. That reduces the risk of stored water freezing even in cold surface conditions.

Frost Protection and Insulation Techniques

Beyond burial depth, additional frost‑protection measures and installation practices can significantly enhance the ability of an underground cistern to remain ice‑free and structurally sound throughout winter.

Additional Frost Protection Strategies

-

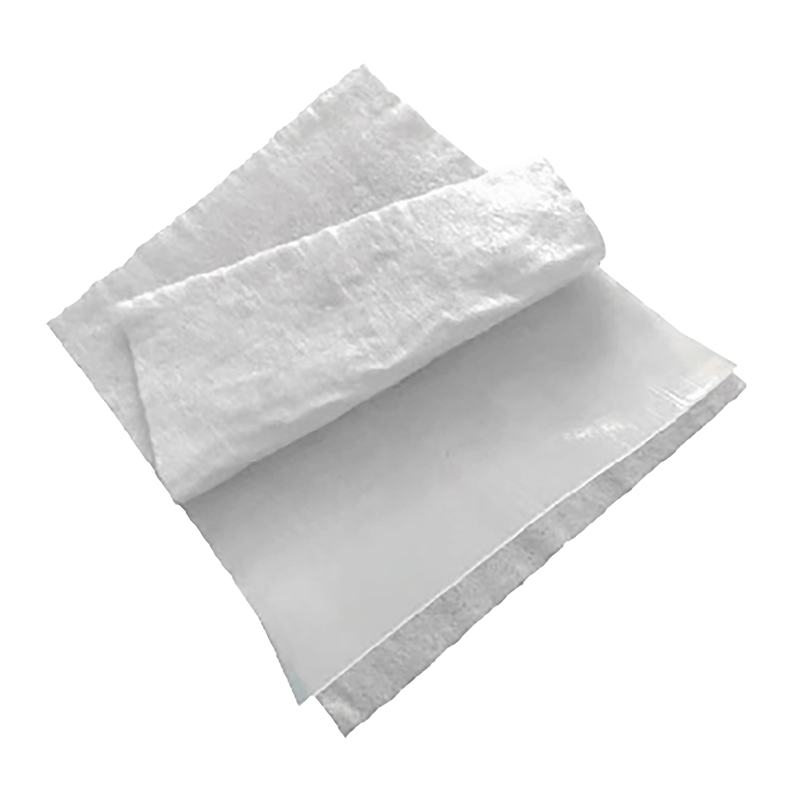

Insulation / thermal barrier: Use of insulating materials (e.g., foam boards, insulation blankets, insulating layers around the cistern) can help reduce heat loss from the soil and buffer against extreme cold pulses. For shallower installations, insulation may allow shallower burial while maintaining freeze protection. This idea is supported by building‑code discussions where “each inch of foam insulation over a water line allows raising the water line by roughly 1 foot” while still avoiding freezing. GreenBuildingAdvisor+1

-

Drainage layers and bedding materials: Providing stable, uniform bedding (e.g., a layer of well‑graded granular or sand material) beneath the cistern reduces risk of point‑contact cold conduction and uneven freeze stress. For underground pipe installations, a minimum of 4 inches of stable bedding is commonly specified. Charlotte Pipe+1

-

Backfill with appropriate materials: Use backfill soil that does not promote rapid heat loss — avoid highly conductive coarse gravel or rock directly against the cistern walls. Instead, use soils with moderate conductivity or add a layer of insulating backfill.

-

Ensure proper drainage and avoid water accumulation: Water pooling near the cistern or high groundwater/perched water levels can pose a freezing risk. Good drainage design (e.g., drainage layers, gravel drains, perforated pipes) helps minimize stagnant water near the tank. This is especially important in cold climates where freezing may persist. zgglxb.chd.edu.cn+1

Recommended Installation Practices for Severe Winters

For regions with severe winters or deep frost penetration, the following practices are recommended to ensure safety and functionality of StormBreaker®:

-

Excavate to sufficient depth: dig to at least the depth recommended for worst seasonal frost penetration plus safety margin (as per local frost‑depth records).

-

Provide uniform bedding: place a stable, compacted bedding layer (e.g., 10–15 cm of well‑graded sand or fine gravel) to support the cistern base and isolate it from cold conductive rock or debris.

-

Backfill carefully with low‑conductivity soils, avoiding large stones or coarse gravels that may act as “cold bridges.”

-

Apply insulation where needed: especially if local frost line is deep but you must install shallower (e.g., due to site constraints), or for shallower top sections (e.g. access ports, manholes). Use foam insulation, insulating blankets, or polystyrene/rigid board to wrap / insulate the top or sidewalls.

-

Design drainage and water‑table control: ensure water cannot accumulate near or above the tank, with perimeter drains or gravel drains; prevent water saturation or perched water near walls.

-

If possible, add frost‑protected foundation design principles (borrowed from frost‑protected shallow foundations): this may include insulation, thermal break layers, moisture‑proofing, and controlled backfill — especially in climates with deep frost or freeze–thaw cycles.

By combining adequate burial depth + good bedding + insulation/backfill + drainage design, the risk of freezing and structural damage to StormBreaker® can be substantially mitigated — making underground storage in cold climates technically feasible.

Why Depth + Frost Protection Matters for Underground Stormwater Cisterns StormBreaker®

-

Passive thermal buffer: Soil around the cistern acts as a large thermal mass, smoothing out temperature fluctuations and preventing rapid freezing of the stored water. Deeper burial increases this buffer.

-

Reduced freeze risk even when surface air is very cold: Because soil temperature lags and changes more slowly than air temperature, water stored underground — below frost line — is far less likely to freeze even when surface air temperatures drop significantly.

-

Structural safety: Proper bedding, backfill, and insulation reduce the risk of cold conduction, point‑load stress, and freeze‑induced pressure that could jeopardize the integrity of the PP tank.

-

Long‑term reliability: With correct installation practices, the system can remain stable across multiple freeze–thaw cycles, enabling multiple‑season or multi‑year use, and supporting resilience for water‑storage / stormwater‑management infrastructure in cold regions.

5. Material Performance and How PP (Polypropylene) Holds Up in Extreme Cold

Polypropylene’s Performance in Cold Environments

Material Characteristics of Polypropylene (PP)

Polypropylene (PP) is widely used in engineering applications because of its advantageous combination of properties — including low density, chemical resistance, relative stiffness, and ease of processing. wiki+2marlinwire.com+2

-

In terms of mechanical properties, PP typically has a density around 0.895–0.93 g/cm³. wiki+1

-

Its crystallinity (in isotactic PP commonly used in structural parts) gives PP a relatively high stiffness (Young’s modulus in range ~1300–1800 N/mm²). Delta Engineering Belgium+1

-

PP is resistant to many chemicals, shows good fatigue resistance, and has low water absorption (making it suitable for water-containing or immersion applications). marlinwire.com+2laminatedplastics.com+2

These properties are why PP is often selected for infrastructure components, pipes, containers, and cistern shells: strength-to-weight ratio, chemical resistance, manufacturability (welding, molding), and relatively stable behavior under a range of temperatures. wiki+2aprios.com+2

Low‑Temperature Behavior: Limits and Risks

However, while PP performs well under many conditions, polymers (including PP) exhibit temperature-dependent mechanical behavior: at low temperatures, many lose ductility and become more brittle. appstate.edu+2Mit Engineering+2

-

The phenomenon is related to a ductile-to-brittle transition (or glass‑transition onset for amorphous fractions): as temperature drops below a certain threshold (often called a “brittle‑transition temperature”), molecular mobility decreases, reducing the ability of polymer chains to deform under stress — leading to brittle fracture under impact or stress. specialchem.com+2Mit Engineering+2

-

For PP, the so-called “glass transition temperature” (Tg) is typically in the range of about –20 °C to 0 °C, depending on crystallinity, tacticity, and additives. Jiga+2wiki+2

-

Many technical datasheets and sources warn that below 0 °C (or around there), PP’s impact strength and toughness degrade; under severe cold, thin‑walled or lightly reinforced PP components may become brittle. camlab.co.uk+2chinaruicheng.com+2

Therefore, while PP’s high melting point (typically ~160–170 °C) shows excellent high-temperature performance and stability for hot applications, its low‑temperature toughness is limited compared to its performance at ambient temperatures. Palmetto Industries+2wiki+2

In short: PP is not immune to cold-induced brittleness; its suitability in freezing environments depends critically on design (wall thickness, reinforcement), loading conditions, rate of stress, and thermal history.

Impact of Freezing Water on PP and StormBreaker®’s Structure

Given that PP may become brittle at sub-zero temperatures, storing water in a PP underground cistern (like StormBreaker®) under freezing conditions raises several material‑behavior and structural‑safety concerns — especially if internal water freezes. Below I discuss key aspects: volume expansion, structural stress, and design mitigation.

The Expansion of Freezing Water

Water expands roughly 9% by volume when it freezes (water → ice). This expansion generates internal pressure if the liquid is confined with little or no room for expansion. For a sealed or partially sealed underground water tank, such expansion can exert substantial stress on the walls of the tank.

If a PP tank remains completely full of water (no air gap or expansion allowance), freezing could cause internal pressures high enough to deform, crack, or rupture the shell — particularly if the shell becomes brittle from low temperature exposure.

Thus, from a design perspective, any underground cistern intended for cold‑climate use must consider water expansion in freeze conditions, and provide structural allowance or buffer — for example:

-

leaving a small headspace (air gap) in the tank (i.e., not filling completely to brim) to allow volume expansion when freezing occurs;

-

designing the tank walls and geometry (wall thickness, shape, reinforcement ribs) to withstand internal pressure during freezing events;

-

specifying installation practices (e.g., partial drain before freeze, or provide drainage / recirculation) in high‑risk cold‑climate zones.

Can PP Structural Shell Withstand Freeze-Induced Stress?

Given the properties of PP, whether a underground stormwater storage PP tank survives freezing depends on several factors:

-

Material ductility at low temperature: Since PP becomes less ductile (more brittle) below its Tg (~ –20 °C to 0 °C), a PP tank exposed to internal ice expansion and external cold simultaneously has increased risk of brittle fracture under stress. wiki+2Mit Engineering+2

-

Wall thickness and reinforcement: Thicker walls or reinforced design (e.g., structural ribs) improve the capacity to resist internal pressure generated by ice expansion. A thin-walled container (like a disposable plastic container) likely fails, as shown by anecdotal tests where thin PP lids cracked at ~ –23 °C. Chemical Education Xchange+1

-

Manufacturing quality and material grade: Using PP grades optimized for toughness (e.g., copolymers, impact-modified PP, PP with additives) can improve low- temperature performance. Recent developments in PP composite materials (e.g., PP blended with HDPE or elastomeric phases) have successfully shifted the brittle–ductile transition to lower temperatures while maintaining mechanical strength. AZoM+1

-

Rate of stress application: Slow freezing (gradual ice formation) may relieve stress more gently than rapid freeze (fast temperature drop), since slow freeze can allow micro-adjustments, ice-lens formation or partial freezing instead of sudden volume expansion. Rapid drop to deep sub-zero while fully filled may maximize risk. This is a common principle in materials under cold‑induced stress; many polymers’ failure under cold is sensitive to strain rate. appstate.edu+2Mit Engineering+2

In practice, for StormBreaker®:

-

If manufactured using a robust, impact-modified PP grade (or using composite PP), with designed wall thickness and internal headspace, the shell may survive moderate freeze cycles without failure.

-

However, under extreme cold (below –10 °C to –20 °C), especially in combination with full water fill and rapid freeze, the risk of shell embrittlement and cracking increases significantly.

Hence, while PP offers many advantages, its low-temperature limitations cannot be ignored — and structural design + operational practices must account for freeze risks.

What This Means for StormBreaker® — Risk vs. Mitigation

Combining material behavior data and freezing‑water physics, we can draw the following insights for using StormBreaker® in cold climates:

Advantages / Potential

-

PP provides a lightweight, weldable, corrosion‑resistant shell suitable for underground storage; under mild cold or temperate winters, the risk is lower.

-

If designed with structural reinforcement and adequate wall thickness, and possibly use of improved PP grades (copolymer / impact‑modified), the tank may resist cold-induced brittleness.

-

With proper installation (burial depth, thermal buffering by soil, drainage), and operational measures (headspace, partial draining before freezing, avoiding full fill in winter), freeze risk can be mitigated.

Risks / Limitations

-

PP’s material ductility decreases at sub-zero temperatures (especially below Tg ~ –20 °C to 0 °C), increasing risk of brittle failure under stress.

-

If water inside freezes and expands, internal pressure may exceed design strength, especially if shell is thin or unreinforced.

-

Rapid freeze cycles, repeated freeze-thaw cycles, or cold + impact or external loads may lead to cracking or failure.

-

Lack of publicly available, long-term data or peer-reviewed studies on large PP underground cisterns subject to freeze cycles — so any cold‑climate use remains partly speculative, requiring conservative design and testing.

What speaks in favor of underground PP tanks (like StormBreaker®) working in cold climates

-

Underground storage tanks benefit from surrounding soil as a thermal buffer: according to a water‑storage industry source, underground tanks “stay warmer in winter due to the insulation that the soil around them provides.” Dunham Engineering+1

-

PP (polypropylene) — the material often used for plastic water tanks — has good durability, chemical resistance, and structural strength for storing water or liquids. Alibaba+1

-

Underground storage tanks avoid many of the exposure issues that aboveground tanks face (wind chill, ambient freezing, snow/ice contact, direct radiation), because soil insulation tends to moderate temperature swings. Dunham Engineering+1

Therefore, in many scenarios — especially where the tank is properly buried and insulated by soil — a PP underground stormwater tank could remain above freezing even if surface air temperatures drop below 0 °C. This is the basic principle behind many buried cisterns used for rainwater harvesting or stormwater detention in temperate climates. Rain Harvesting Supplies+1

Conclusion of Chapter 5

Polypropylene (PP) offers many advantages that make it a suitable choice for underground stormwater cisterns, such as StormBreaker®. It has excellent chemical resistance, high strength-to-weight ratio, and durability under a variety of conditions. However, its behavior in extreme cold does require careful consideration. While PP maintains structural stability at high and moderate temperatures, it can become more brittle and less impact-resistant at sub-zero temperatures.

That said, StormBreaker® is not made from pure PP; it is a composite material, which enhances its toughness and resistance to brittle failure. The reinforced design of StormBreaker® ensures that its structural integrity is maintained even under cold weather conditions, and the system’s high pressure and load-bearing capabilities reduce the risk of failure in freezing environments. The design of StormBreaker® accounts for freeze-induced stress, with careful attention to wall thickness, reinforcement structures, and internal headspace, allowing it to absorb the expansion of frozen water without compromising its functionality.

The risk of failure from freezing water is greatly minimized unless exposed to extreme low temperatures or rapid freezing events. Therefore, StormBreaker® can reliably function in cold climates with proper installation practices, provided that site-specific conditions (such as frost depth, soil type, and drainage) are taken into account. By adopting a conservative design approach and following recommended installation guidelines for freeze risk mitigation, StormBreaker® offers long-term resilience in cold environments.

6. No Universal Temperature Threshold — Why Cold‑Climate Use Requires Site‑Specific Considerations

Why We Cannot Set a Universal “Lowest Safe Temperature”

Variability of Environmental Conditions

It is tempting to want a simple rule such as “StormBreaker® is safe down to –X °C air temperature.” However, the reality of ground freezing and underground storage is much more complex — and that complexity means no single air‑temperature threshold can reliably guarantee safe operation everywhere. The key reasons are:

-

Frost line depth (freezing depth) varies widely by region. What constitutes a “safe burial depth” in one region may be completely insufficient in another. For example, frost depth across the contiguous United States ranges from nearly 0 up to ~8 ft (≈ 2.4 m), depending on local climate, soil, and historical freeze data. wiki+1

-

Soil type, moisture, groundwater conditions, and soil thermal properties differ significantly. Soil texture, porosity, water content, capillarity, and thermal conductivity all influence how freezing propagates, how water migrates, and whether ice lenses form — affecting frost penetration and frost‑heave risk. wiki+2PMC+2

-

Surface conditions and ground cover, drainage, backfill and installation quality further change freezing behavior. Snow cover, vegetation, pavement, insulation, drainage layers — all these influence soil temperature dynamics, freezing‑front progression, and soil‑water behavior. wiki+2wiki+2

-

Interaction between soil and underground structure can distort idealized models. The presence of a buried tank or pipe alters soil temperature distribution, moisture migration, and stress distribution during freeze‑thaw cycles. Recent experiments show that buried pipes significantly alter soil thermal fields under frost‑heave conditions, causing unexpected strain and soil‑structure interaction effects. ResearchGate+1

Because of this variability — and the many interacting factors — it is not scientifically defensible to claim a universal “lowest air‑temperature” under which an underground water storage system like StormBreaker® will always remain safe and ice‑free.

Engineering Judgment: What Truly Determines Safe Operation

Given the above, in practice the safety and reliability of an underground storage system under cold conditions depends far more on site‑specific design, soil conditions, installation quality, and frost protection measures than on ambient air temperature alone. Key determinants include:

-

Whether the tank is buried below the local maximum frost penetration depth (frost line) — with appropriate safety margin.

-

Soil type and moisture conditions — soils with low permeability and suitable thermal/ hydraulic characteristics are much less susceptible to deep freezing or dangerous ice‑lens formation.

-

Installation quality: backfill, drainage, bedding, insulation, avoidance of cold conduction paths.

-

Design of the tank itself: structural strength, allowance for ice expansion (if freezing happens), pressure tolerance, and material behavior under cold + internal stress.

-

Long‑term freeze–thaw cycles, groundwater fluctuation, external loads, and maintenance regime — all can affect system performance over time, especially under repeated freezing and thawing seasons.

Therefore, engineering judgment — informed by site investigation, soil testing, frost‑line data, design for worst‑case freeze scenarios — is essential to determine whether StormBreaker® can be safely used at a given location.

Examples of Failures (or Damage) Due to Inadequate Installation or Ignoring Local Conditions

Real‑world engineering and geotechnical experience strongly warn against relying only on air temperature or simple assumptions. Several documented failure mechanisms highlight why:

-

Frost‑heave induced damage to buried pipelines or foundations: In cold regions, frost‑heave (soil expansion caused by freezing water/ice lens formation) has frequently caused damaging uplift and deformation of pipelines or structural foundations when they were installed too shallow or soil conditions were not properly accounted for. Wiley Online Library+2Intech Anchoring Systems+2

-

Pipe‑soil interaction causing deformation under freeze‑thaw: A recent experimental study demonstrated that under frost‑heave soil conditions, buried pipes experienced significant strain and deformation. The extent of deformation increased as ambient temperature dropped, especially when soil moisture was high and burial depth insufficient. ResearchGate

-

Settlement and structural failure of buildings due to frost‑heave in foundations: Foundations of houses or buildings constructed without sufficient frost protection — e.g., installed above frost line or without proper drainage/backfill — often suffer from cracking, uneven settlement, structural distress after the first or second freeze‑thaw cycle. everdrytoledo.com+2University of West Virginia Research+2

These examples illustrate that even simple underground structures like water pipes or shallow foundations — which are far less complex than a full cistern — can fail when frost effects are overlooked. That reinforces why it is unreasonable to expect a one‑size‑fits‑all “temperature safe zone” for underground tanks.

What This Means for Cold Climate Deployment of Underground Stormwater Cisterns StormBreaker®

Because of the large variability in climate, soil, ground conditions, and installation practices, there is no universal “safe air temperature threshold” that guarantees safety and frost‑free operation for StormBreaker® (or any underground water storage system).

Instead, safe and reliable cold‑climate use must be based on site‑specific evaluation, soil and frost line data, design adapted to local conditions, and proper installation and maintenance. For any given location where winter temperatures may drop below freezing, the question should not be “Is air temperature below –X °C?”, but:

-

“What is the local frost depth and soil condition?”

-

“At what depth and under what backfill/drainage conditions will the tank be placed?”

-

“Is the soil thermal and hydraulic behaviour adequate to prevent dangerous freeze penetration or ice‑lens formation?”

-

“Is the tank designed to tolerate possible freeze stresses (internal pressure from freezing water, frost‑heave forces from soil)?”

Only with such comprehensive, context‑aware analysis and engineering judgment can one responsibly conclude whether stormwater storage via StormBreaker® is feasible in a particular cold‑climate project.

7. Key Considerations for Installing StormBreaker® in Cold Climates

Site‑Specific Recommendations for Cold‑Climate Installation

Perform a Soil and Site Investigation — Pre‑Installation Survey Is Essential

Before installing StormBreaker® (or any underground water storage / cistern) in a cold‑climate region, the first critical step is to undertake a site‑specific soil and geotechnical investigation. The primary goals of this investigation should include:

-

Determine local frost depth (frost line / maximum freeze penetration depth): By referencing climate data and historical ground‑freeze records, combined with modeling or local frost‑depth tables, estimate how deep the ground freezes under worst‑case winter conditions. This determines how deep StormBreaker® must be buried to stay safely below freeze risk. As recommended by cold‑climate stormwater design guidance, underground storage or structural elements should be placed below frost line to “protect them from frost heave and prevent water from freezing.” fnsb.gov+1

-

Characterize soil type, texture, and properties: Collect soil samples (boreholes, test pits) to classify soil texture (clay / silt / sand / gravel), permeability, porosity, moisture content, groundwater level, and drainage conditions. This is because soil thermal conductivity, moisture content, permeability, and thermal inertia dramatically affect freezing behavior and frost propagation.

-

Evaluate groundwater / hydrogeologic conditions: Determine whether there is a high water table, perched water zones, seepage, or seasonal groundwater fluctuations that may bring water close to or around the tank — since presence of groundwater or seepage increases frost risk.

-

Consider overlying surface cover and land use: Take into account surface conditions (snow cover, vegetation, pavement or asphalt, landscaping), which influence heat loss, insulation, soil cover temperature profile, and freezing dynamics.

-

When possible, simulate or model freeze‑thaw conditions: Use frost‑penetration models, local freeze‑thaw cycle data and soil thermal property data to estimate ground temperature variation over winter, determining safe burial depth and freeze risk.

Only after such a thorough site‑specific investigation can one reasonably design the installation for cold‑climate performance. Blanket assumptions (e.g., “our tank resists –25 °C, so we’re fine anywhere”) are insufficient and risky without soil/site context.

Best Practices for Cold‑Climate Installation: Backfill, Drainage, Insulation & Bedding

Once site and soil conditions are known, following best installation practices significantly improves the likelihood that StormBreaker® will remain functional and frost‑safe. Key recommended practices include:

-

Use appropriate bedding and backfill material: When placing the tank, first provide a stable bedding layer (e.g., well‑graded sand or fine gravel). Then backfill in controlled lifts — compacting layer by layer from the outside toward the tank — to remove voids and ensure uniform support. This practice reduces risk of uneven settlement or structural stress. ntotank.com+1

-

Prefer backfill materials with moderate thermal conductivity / good drainage: Avoid using coarse, highly conductive gravel or rock directly against the tank walls, which might create “cold bridges.” Instead use backfill or soil with moderate conductivity, good insulation potential, and controlled moisture/ drainage characteristics, to minimize conductive heat loss from the tank to freezing soil. Soil / backfill compaction and uniformity are also important to avoid preferential water flow or freeze‑paths.

-

Provide drainage layers and perimeter drains if necessary: To prevent water accumulation near the tank (which would increase freeze risk), install drainage layers, gravel drains, perforated pipes or other drainage systems around the cistern. Good drainage is one of the foundations of frost‑safe underground installations. This parallels standard foundation and below‑grade drainage design practices for buildings. bcbec.com+1

-

If needed, apply external insulation or thermal barrier around the tank: In sites where frost depth is high, or where burial depth is constrained (e.g., shallow ground, groundwater, or structural limitations), consider adding insulating materials — such as rigid foam (e.g., extruded polystyrene boards), spray foam or other insulation blankets around the tank walls or top. This technique is widely adopted in earth‑shelter construction or cold‑region underground structures to reduce heat loss and prevent freezing. wiki+1

-

Ensure tank is seated level and stable before backfilling: During installation, set the tank level on the bedding material, without water load, then backfill carefully to avoid point loads, sharp stones, or voids — which can become stress concentration points when soil freezes or hydraulics shift. Lifting and installation should use designed lifting lugs/points; never lift with water inside. ntotank.com

-

Compact backfill in controlled layers: Backfilling around the tank should be done in layers (e.g., 12‑inch / ~30 cm lifts), each compacted from outside toward the tank to eliminate voids and ensure uniform soil contact and support — preventing uneven freeze‑thaw stress distribution. ntotank.com+1

Adherence to these best practices markedly reduces the risk of frost‑induced structural damage, uneven freezing, or tank movement.

Emergency Considerations & Freeze‑Risk Mitigation Measures

Even with careful design and installation, extreme cold, unusually long freeze periods, or unanticipated groundwater / drainage conditions might still pose freezing risks. It is therefore prudent to design for fail‑safe mechanisms and monitoring, especially for installations in severe cold regions. Recommendations include:

-

Install water‑temperature sensors or monitoring probes inside the tank (and optionally in surrounding soil): During the first winter(s), monitor water temperature and soil temperature around critical zones to verify that freezing does not occur. If water temperature approaches freezing, remedial action can be taken (e.g., partial draining, heating, insulation).

-

Design for periodic draining (or partial draining) before deep freeze seasons: If the region experiences long, deep freeze periods, allowing a controlled drainage (or lowering fill level) before freeze can mitigate freeze‑expansion risk, especially if tank lacks freeze‑proof insulation or heating.

-

Provide overflow or pressure‑relief mechanisms if freezing occurs: For example, design the tank with expansion capacity (air‑gap/headspace) — do not fill absolutely to brim — so that if partial freezing occurs, ice expansion will have space to expand without imposing excessive pressure on the tank walls.

-

Consider passive or active heating / ground‑temperature maintenance in extreme climates: For very harsh cold or freeze–thaw cycles, adding a shallow ground‑heat source, heating coil, or insulated access riser might be considered (although such measures increase cost and complexity), analogous to frost‑mitigation measures used in cold‑region infrastructure like tunnels, pipelines or earth‑sheltered buildings. MDPI+1

-

Establish maintenance and inspection plan: After installation, schedule periodic inspection (especially post‑winter) to check for any signs of deformation, cracking, settlement, leakage or frost‑heave effects. Early detection allows remediation before catastrophic failure.

Summary: A Checklist for Cold‑Climate Underground Stormwater Management Systems – StormBreaker® Installation

Below is a summary checklist of recommended actions and design considerations when installing StormBreaker® under cold-climate or freeze‑risk conditions:

-

Conduct soil and geotech investigation (frost line, soil type, moisture, groundwater).

-

Choose burial depth based on local frost line + safety margin.

-

Provide stable bedding and proper backfill, compacted in controlled layers.

-

Use appropriate backfill materials, avoid coarse rock “cold bridges.”

-

Provide good drainage around tank — perimeter drains, gravel layers, avoid stagnant water near walls.

-

Consider external insulation if local frost risk is high or burial depth limited.

-

Ensure tank design and fill strategy includes headspace for potential freeze expansion, or plan for seasonal draining.

-

Install monitoring sensors (water & soil temperature) if feasible.

-

Plan maintenance/inspection schedule, especially post‑winter.

-

For severe climates: evaluate need for heating or frost‑mitigation systems (active or passive).

Why These Practices Matter for Underground Stormwater Management Systems StormBreaker®’s Reliability

Implementing this comprehensive, site‑specific approach ensures that StormBreaker® does not rely solely on its material properties or a “one‑size‑fits-all” guarantee of freeze‑resistance. Instead, it embeds engineering prudence, soil‑geology awareness, and construction best practices into the installation — which together offer a realistic path to reliable underground stormwater storage in cold regions.

Given the variability in climate, soil, groundwater and frost risk across different geographic areas, this tailored approach significantly increases the chances of long-term system integrity, avoids freeze‑related failures or water loss, and builds credibility for StormBreaker® as a viable solution for cold‑climate stormwater management projects.

8.Can Underground Stormwater Management PP Tanks Withstand Sub‑Zero Surface Temperatures in Cold Regions?

Under the Right Conditions, Yes , StormBreaker® Can Work in Cold Climates— But No Guarantee Without Proper Design .

After thorough examination of the factors affecting StormBreaker®’s performance in cold environments — including frost line depth, soil type, thermal inertia, and material behavior of polypropylene (PP) — it is clear that StormBreaker® can indeed operate reliably in cold climates. However, this is only possible if the installation guidelines are strictly followed, with particular attention to:

-

Proper burial depth: Ensure the cistern is installed below the local frost line with an adequate safety margin, which is crucial in preventing freeze damage.

-

Site-specific adjustments: Incorporate the soil’s thermal properties, moisture content, and drainage capacity into the design to ensure that freezing does not compromise the system.

-

Frost protection measures: Use external insulation, suitable backfill, and drainage solutions to minimize heat loss and reduce the risk of freeze‑related damage.

Under these conditions, StormBreaker® can be an effective and durable solution for stormwater management in regions that experience freezing temperatures, offering long-term benefits like flood mitigation, groundwater recharge, and enhanced urban resilience.

What Determines Success — Key Conditions & Design/Installation Requirements

For an underground PP tank like StormBreaker® to work reliably in cold, sub-zero surface temperature environments, the following conditions or design standards are important:

-

Thorough site assessment: Conducting detailed soil and frost depth studies to determine appropriate burial depths and frost protection strategies.

-

Precise installation practices: Ensuring that the tank is installed with proper backfill, drainage, and thermal protection (if required) to withstand freeze‑thaw cycles.

-

Material selection: Using high-quality polypropylene (PP) and considering potential material brittleness at sub-zero temperatures, especially for extreme cold zones.

-

Adequate soil insulation / thermal buffering — the tank must be buried sufficiently deep, and soil around it must have good thermal inertia (not overly conductive, not overly free‑draining soil that allows cold to penetrate quickly).

-

Proper tank design — the tank should be designed or specified with adequate wall thickness, structural strength, possibly reinforcements — particularly to resist internal pressure if water freezes.

-

Drainage and moisture control around the tank — preventing water pooling, groundwater contact, or soil saturation near the tank reduces the risk of ice formation around or in the tank.

-

Optional insulation or freeze‑protection measures — even underground tanks may benefit from insulation blankets, frost‑protection layers, or drainage/perimeter design to guard against deep soil freezing. Some industry literature suggests insulating or heating for plastic tanks used in freezing climates. Go To Tanks+1

-

Maintenance / monitoring / contingency plans — in cold climates, it’s prudent to monitor water temperature, possibly leave some air volume (headspace) to allow for ice expansion, or partially drain the system before prolonged freeze periods.

By designing with these factors in mind, StormBreaker® can continue to provide reliable, freeze-resistant storage for stormwater systems in even the harshest winter climates.

Future Opportunities

As global temperatures rise and weather patterns become more unpredictable, stormwater management is gaining increasing attention. Cold-climate areas that face heavy snowfall and sub-zero temperatures represent a significant opportunity for expansion of StormBreaker® into new markets.

-

Adaptation to varying climates: With the right adjustments in installation procedures and product design, StormBreaker® can be tailored to meet the specific demands of cold regions. For example, incorporating additional insulation layers or using reinforced materials in areas where sub-zero temperatures persist for extended periods.

-

Growing market potential: The demand for sustainable, long-lasting stormwater solutions is set to increase, and positioning StormBreaker® as the go-to product for cold-climate stormwater management could unlock new business opportunities in regions like Canada, Scandinavia, the U.S. Midwest, and parts of Russia.

By focusing on product adaptation and responsible, customized installation, StormBreaker® can lead the way in stormwater management for cold-climate applications — ensuring that infrastructure remains resilient, reliable, and safe year-round.

9. FAQ (Frequently Asked Questions)

Q1: Can StormBreaker® be installed in regions where the temperature regularly drops below −10°C?

Answer: Yes, StormBreaker® can be installed in regions where temperatures drop below −10°C, provided that the installation follows the guidelines for frost depth, soil suitability, and frost protection. Key factors such as burial depth, soil type, and frost protection measures (like insulation and drainage) are crucial in ensuring that the system remains operational and free of damage.

Q2: What is the minimum installation depth for StormBreaker® in cold climates?

Answer: The minimum installation depth for StormBreaker® should be below the local frost line to ensure the system is protected from freezing. This typically ranges from 1.2 meters (4 feet) in regions with moderate frost to 2.5 meters (8 feet) in areas with severe winter conditions. Always refer to local frost depth recommendations for your region.

Q3: How does polypropylene (PP) behave in extremely cold temperatures?

Answer: Polypropylene (PP) is generally durable and performs well in sub-zero conditions. However, its brittleness increases as temperatures drop below its glass transition temperature (~–20°C). In extremely cold climates, PP can become more prone to cracking if subjected to sudden impacts or freeze-induced stress. This is why proper tank design (e.g., reinforced walls and headspace for water expansion) and site-specific installation are critical to prevent damage.

Q4: How do I ensure that StormBreaker® stays functional if freezing water is a concern?

Answer: Several measures can be taken to ensure StormBreaker® remains functional even in freezing conditions:

-

Install the cistern below the frost line to avoid freezing soil and water.

-

Ensure proper drainage to prevent water accumulation near the tank.

-

Leave an air gap inside the tank to allow for water expansion during freezing (if the system is not regularly drained).

-

Add insulation if necessary to further protect against freezing, especially in shallow burial situations.

Q5: Can StormBreaker® be used in regions with permafrost or continuous freezing?

Answer: While StormBreaker® is designed for cold climates, it is not recommended for installation in areas with permafrost or continuous freezing. In these environments, the ground remains frozen year-round, and the conditions are too extreme for typical underground cisterns. If installation in permafrost regions is required, more advanced engineering solutions (such as heating elements or thawed soil pockets) may be needed to ensure proper system functionality.

Q6: What should I do if I suspect freezing might affect my installation during winter?

Answer: If freezing is a concern during installation, consider monitoring soil and water temperatures to ensure the tank remains unfrozen. Additionally, partial draining before extreme cold periods or using frost‑protected foundation techniques can help mitigate freeze risk. If freezing is detected during winter, you may need to provide temporary insulation or active heating solutions to protect the system.

Call to Action

StormBreaker® is the perfect solution for cold‑climate stormwater management when properly designed and installed. Don’t let freezing temperatures prevent your infrastructure from working efficiently. Whether you’re planning a new installation or upgrading an existing system, StormBreaker® can meet your needs — with tailored solutions for every environment.

Get in Touch with Us Today:

-

Request a Consultation: Let our engineers assess your site and provide recommendations for safe and effective installation in cold climates.

-

Download Our Product Brochure: Learn more about StormBreaker®’s features, benefits, and technical specifications.

-

Speak with a Specialist: Contact us directly for any specific questions or technical support for your cold‑climate project.

Don’t let the cold stop you from protecting your community — choose StormBreaker® for robust, long-term stormwater solutions.