Introduction

Water is the backbone of every thriving city, industrial facility, and community. Yet, as urbanization accelerates and climate change intensifies, the way we manage stormwater and supply water to critical sectors has reached a tipping point. Flooding events are becoming more frequent, while water scarcity threatens industries and municipalities across North America.

This is where underground rainwater storage systems come into play. They are not just hidden infrastructure components buried beneath our feet; they are strategic investments in climate resilience, sustainability, and cost savings. For developers, engineers, contractors, and policymakers in the United States, Canada, and Mexico, adopting underground rainwater harvesting solutions is rapidly becoming both a necessity and a competitive advantage.

In this article, we will explore the technology, applications, benefits, and trends of underground rainwater tanks and systems—providing a professional, SEO-optimized guide for industry stakeholders seeking effective stormwater and water-reuse solutions.

1. Understanding Underground Rainwater Storage

What is Underground Rainwater Storage?

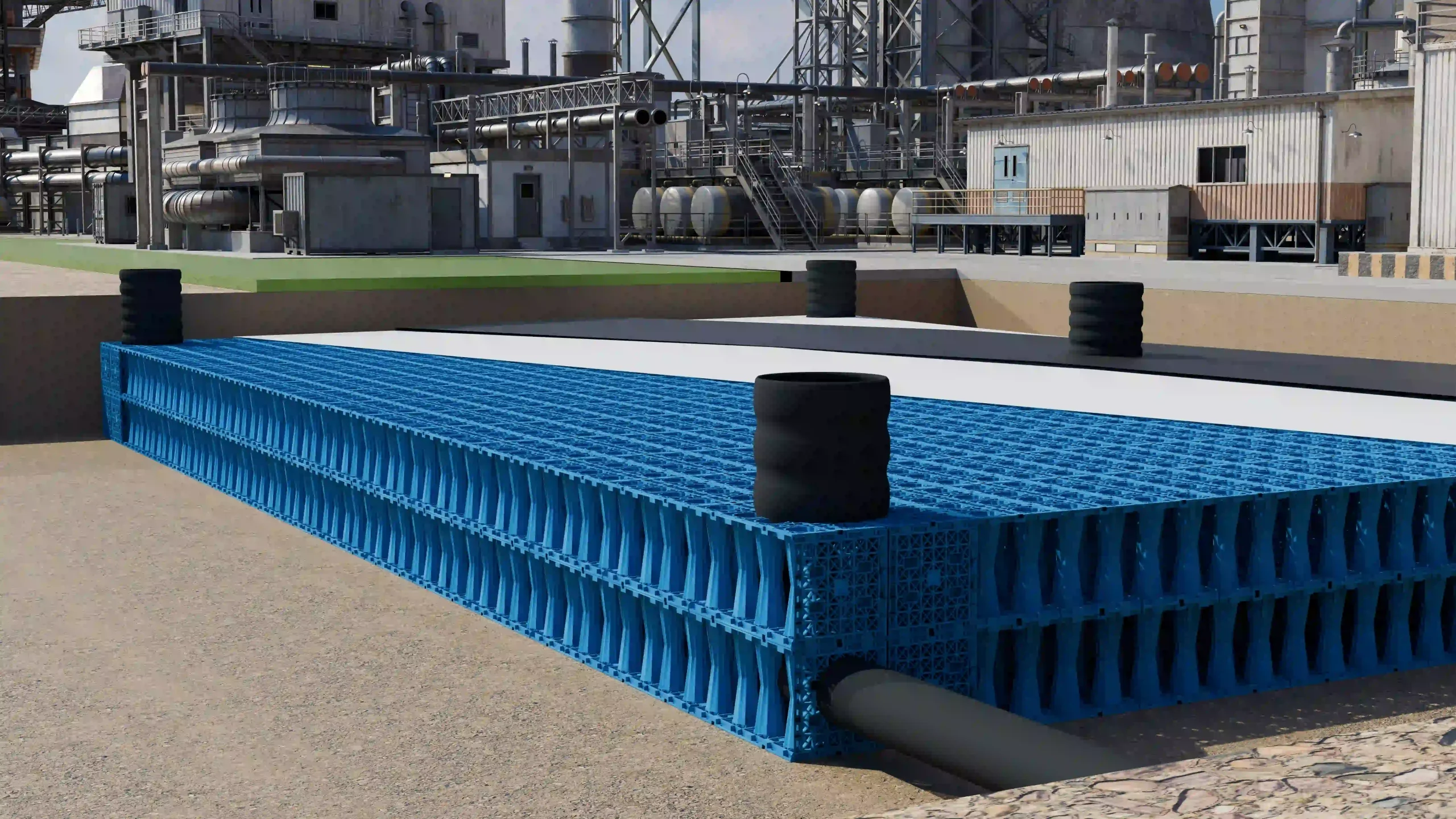

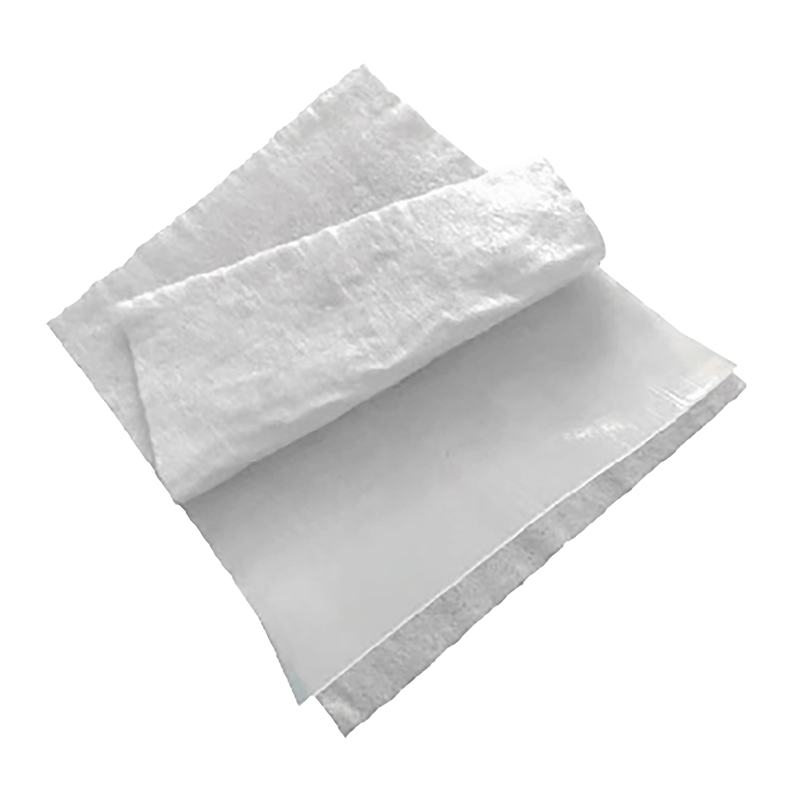

Underground rainwater storage refers to systems designed to collect, filter, and store rainwater runoff in buried tanks or geocellular modules. Unlike traditional above-ground tanks, these systems are installed below the surface, allowing valuable land space to remain usable while securing long-term water supply.

Key components include:

-

Collection inlets and filters: Capture runoff from roofs, roads, and paved areas.

-

Modular storage tanks or geocellular crates: High-void, structural modules capable of withstanding heavy loads from vehicles and buildings.

-

Access chambers and pumps: Enable inspection, cleaning, and water distribution.

-

Integration with reuse systems: Supply stored rainwater for irrigation, cooling, industrial processes, or non-potable applications.

Why Go Underground?

Above-ground tanks often face challenges: limited space, exposure to UV degradation, aesthetic concerns, and restricted storage capacity. Underground systems overcome these barriers, delivering:

-

Space efficiency: No disruption of surface use for parking, landscaping, or pedestrian areas.

-

Structural resilience: Systems like YD StormBreaker® and StormFlow® tunnels offer tested load capacities exceeding 32T–60T, making them suitable for airports, highways, and commercial facilities.

-

Longevity and durability: Manufactured from recycled PP/HDPE, designed to last decades with minimal maintenance.

2. Core Benefits of Underground Rainwater Harvesting Systems

2.1 Structural Integrity and Load Performance

Underground rainwater tanks such as YD StormBreaker® are manufactured from polypropylene (PP), a material known for its high stiffness-to-weight ratio, chemical resistance, and structural reliability. Unlike HDPE tanks, which may deform under sustained heavy loads, PP modules maintain dimensional stability, making them suitable for dynamic traffic conditions such as highways, container yards, and airport pavements. StormBreaker® modules are engineered and independently tested for 32T, 45T, and 60T load capacities, ensuring compliance with CIRIA C737 and EN load distribution standards.

2.2 Hydraulic Efficiency and System Scalability

Above-ground tanks are typically limited in configuration and inflow capacity, often resulting in hydraulic short-circuiting or overflow during peak rainfall events. By contrast, the geocellular matrix design of StormBreaker® promotes uniform flow distribution and modular scalability. Systems can be configured to provide both detention (attenuation) and retention (reuse) functions, enabling design flexibility from small-scale commercial projects to mega-infrastructure installations exceeding millions of liters.

2.3 Lifecycle Sustainability

One of the most overlooked advantages of underground PP systems is their service life expectancy exceeding 50 years. Since modules are shielded underground, they are not exposed to UV degradation, freeze–thaw stresses, or vandalism—factors that significantly reduce the lifespan of above-ground cisterns. Furthermore, PP modules are fully recyclable, aligning with circular economy and ESG reporting frameworks. This gives developers and municipalities not only an operational advantage but also a sustainability credential when pursuing LEED, BREEAM, or CSA Green Building credits.

2.4 Optimized Land Use in High-Value Developments

For North American cities where land cost is a premium, freeing surface space is crucial. Installing underground tanks beneath parking lots, logistics platforms, or landscaped plazas maximizes land utilization while maintaining stormwater compliance. In contrast, above-ground storage facilities require designated land parcels, creating opportunity costs for developers and operators.

3. Technical Overview: Types of Underground Rainwater Tanks

3.1 Geocellular Modular Tanks

-

Void Ratio: Up to 95% for maximum storage volume.

-

Load Capacity: Options from 32T to 60T, tested to CIRIA C737 and EN standards.

-

Applications: Parking lots, industrial sites, airports, logistics hubs.

3.2 Infiltration Tunnels

-

Long hollow structures designed to gradually infiltrate water into the soil.

-

Effective in areas requiring groundwater recharge and SUDS compliance.

3.3 Concrete Cisterns

-

Traditional approach, but less flexible and more costly in installation compared to modular PP systems.

3.4 Hybrid Systems

-

Combine storage with filtration units (e.g., YD StormInlet®) and root management systems (e.g., StormVault®), creating integrated stormwater management solutions.

4. Technical Considerations of StormBreaker® Systems

4.1 Material Properties: PP vs. HDPE

-

Polypropylene (PP) offers higher compressive strength, rigidity, and chemical resistance, making it particularly suited for long-term static and dynamic load conditions.

-

High-Density Polyethylene (HDPE), while durable, has a lower modulus of elasticity, which can result in creep deformation under continuous heavy loads.

-

StormBreaker®’s PP composition ensures structural resilience under both shallow and deep-burial conditions, tested to perform reliably at depths exceeding 5–6 meters with concrete backfill.

4.2 Compliance with International Standards

StormBreaker® systems are engineered to meet or exceed key North American and global benchmarks:

-

CIRIA C737 (UK) for structural testing of geocellular systems.

-

ASTM standards for material integrity and durability.

-

CSA and NPDES requirements in Canada and the United States for stormwater detention and water quality compliance.

4.3 Maintenance and Operational Protocols

While underground systems are concealed, they remain accessible through inspection chambers and jetting channels, allowing for efficient inspection and cleaning cycles. Advanced configurations integrate sediment pre-filtration (StormInlet®) and root management solutions (StormVault®) to further extend service life and reduce maintenance frequency.

5. Ground vs. Underground Rainwater Storage (StormBreaker®) – Comparison Table

| Dimension | Above-Ground Rainwater Storage | Underground Rainwater Storage (YD StormBreaker® – PP Modules) |

|---|---|---|

| Material Technology | Steel, GRP, or HDPE tanks; prone to UV degradation, corrosion, and thermal expansion | High-strength Polypropylene (PP) with 95% void ratio; chemically inert, resistant to corrosion, certified under CIRIA C737/EN standards |

| Structural Load Capacity | Typically designed only for hydrostatic pressure; cannot support significant external loads | StormBreaker® modules engineered for 32T/45T/60T load ratings, enabling installation under parking lots, heavy-duty roads, airports, and industrial platforms |

| Hydraulic Performance | Single large-volume tanks with limited flow distribution efficiency | Modular matrix design enhances inflow/outflow balance, prevents hydraulic short-circuiting, and supports scalable detention/attenuation systems |

| Space Efficiency | Occupies visible surface area; difficult in dense urban or industrial settings | Buried beneath ground; optimizes land use for buildings, logistics yards, landscaping, or green infrastructure above system |

| Durability & Lifecycle | Exposed to sunlight and temperature fluctuations; UV degradation and algae formation reduce lifespan (10–20 years typical) | Underground PP modules shielded from UV and surface stresses; designed service life 50+ years under static and dynamic load conditions |

| Water Quality Management | Exposure to light → algae growth; higher biological activity; frequent cleaning needed | Stable underground temperature; reduced microbial growth; integration with pre-filtration (StormInlet®) ensures long-term water quality |

| Maintenance & Inspection | Direct manual access; easier cleaning but frequent due to contamination risk | Access via inspection shafts; cleaning intervals extended due to closed system and integrated filtration; requires technical O&M planning |

| Climate Adaptation | Performance affected by freeze–thaw cycles, evaporation, and temperature extremes | Subsurface environment buffers against extreme heat/cold; proven reliability in North America’s hot-summer/hard-winter climates |

| Regulatory Compliance | Limited contribution to stormwater attenuation credits; often excluded from SuDS/LEED frameworks | Recognized under SuDS, LEED, BREEAM, CSA standards; supports municipal flood mitigation, infiltration, and water reuse regulations |

| CAPEX & OPEX | Lower initial capital expenditure but higher operational/maintenance costs due to algae, structural wear, and space constraints | Higher CAPEX (excavation, installation), but lower lifecycle cost thanks to durability, reduced O&M, and water reuse savings |

| Resilience & Security | Vulnerable to vandalism, accidents, external contamination, and extreme events | Fully concealed, structurally integrated, tamper-resistant, and resilient against flooding or seismic impacts |

6. Regional Applications in North America

6.1 United States

-

Airport Infrastructure (e.g., Orlando, Dallas-Fort Worth): 60T-rated PP modules withstand aircraft taxi loads while delivering high-volume stormwater detention.

-

Commercial Real Estate (California, New York): Integration with LEED-certified designs enhances property valuation and reduces long-term operating costs.

6.2 Canada

-

Urban Redevelopment (Toronto, Montreal, Vancouver): Municipal mandates encourage stormwater attenuation and infiltration; StormBreaker®’s PP resilience ensures performance under freeze–thaw conditions.

-

Mining and Industrial Facilities: Modular underground tanks provide sustainable process water supply while meeting CSA standards.

6.3 Mexico

-

Water-Stressed Regions (Monterrey, Mexico City): Retention tanks secure non-potable water for industrial and residential consumption.

-

Hurricane-Prone Regions (Yucatán, Veracruz): Attenuation systems mitigate peak stormwater surges, protecting communities from flash floods.

7. Future Trends in Underground Rainwater Harvesting

-

Smart Sensor Integration: Embedding IoT-based monitoring for real-time data on storage levels, water quality, and infiltration rates.

-

Hybrid Infrastructure: Combining PP geocellular tanks with permeable pavements and bioretention systems to create multi-functional SuDS solutions.

-

Resilient City Design: Growing adoption of underground rainwater harvesting as a baseline infrastructure requirement in master-planned developments across North America.

8. Why Yude Rain Eco’s StormBreaker® System is the Preferred Choice

-

Material Advantage: Proprietary PP construction ensures superior rigidity, load-bearing, and lifecycle performance compared with conventional HDPE solutions.

-

Proven Load Ratings: Independent testing validates 32T, 45T, and 60T modules for heavy-duty applications.

-

Global Case Studies: Installed in airports, industrial zones, and urban centers worldwide, now expanding across U.S., Canadian, and Mexican markets.

-

Sustainability Alignment: Fully recyclable PP modules contribute to LEED credits and ESG targets, positioning stakeholders for regulatory compliance and investor approval.

9. Next-Gen Upgrade: StormBreaker® 80T

As infrastructure demands continue to grow, Yude Rain Eco is preparing to launch the StormBreaker® 80T, an ultra-high load capacity underground rainwater storage module.

-

Unprecedented Load Capacity: Engineered to withstand 80T static and dynamic loads, far exceeding current market standards.

-

Application Scenarios: Perfectly matched for airports, seaports, freight terminals, and mega-logistics hubs, where heavy machinery and continuous traffic demand extreme resilience.

-

Material Excellence: Constructed from high-rigidity polypropylene (PP), ensuring long-term durability under the most challenging environments.

-

Scalable Integration: Compatible with existing StormBreaker® modules, allowing mixed-load system configurations for phased development projects.

-

Future-Ready Design: Developed in line with CIRIA C737 and ASTM/CSA compliance frameworks, aligning with North American infrastructure requirements.

The StormBreaker® 80T represents the next leap in underground rainwater harvesting and stormwater attenuation — delivering unmatched strength, sustainability, and scalability.

FAQs: Underground Rainwater Storage Systems

Q1: How long do underground rainwater tanks last?

High-quality PP systems can last 50+ years with minimal maintenance.

Q2: Can these systems be installed under heavy traffic areas?

Yes. With load ratings up to 60T, Yude’s systems are suitable for roads, airports, and industrial facilities.

Q3: Is water quality safe for reuse?

With proper filtration and treatment, harvested rainwater is ideal for irrigation, industrial processes, and non-potable domestic use.

Q4: What is the ROI for underground rainwater harvesting?

ROI varies, but industries typically recover costs in 3–7 years through reduced water bills, flood prevention savings, and regulatory compliance incentives.

Q5: Do systems help with LEED or green building certification?

Yes. Installing underground rainwater harvesting systems contributes to water efficiency and sustainable site credits under LEED and other green building programs.

Call to Action

If you are a developer, engineer, or municipal planner in the U.S., Canada, or Mexico, now is the time to integrate underground rainwater storage solutions into your projects.

Contact Yude Rain Eco today to discuss tailored solutions for your infrastructure needs:

[email protected]

Future-proof your infrastructure. Save costs. Build sustainably. Choose Yude Rain Eco.